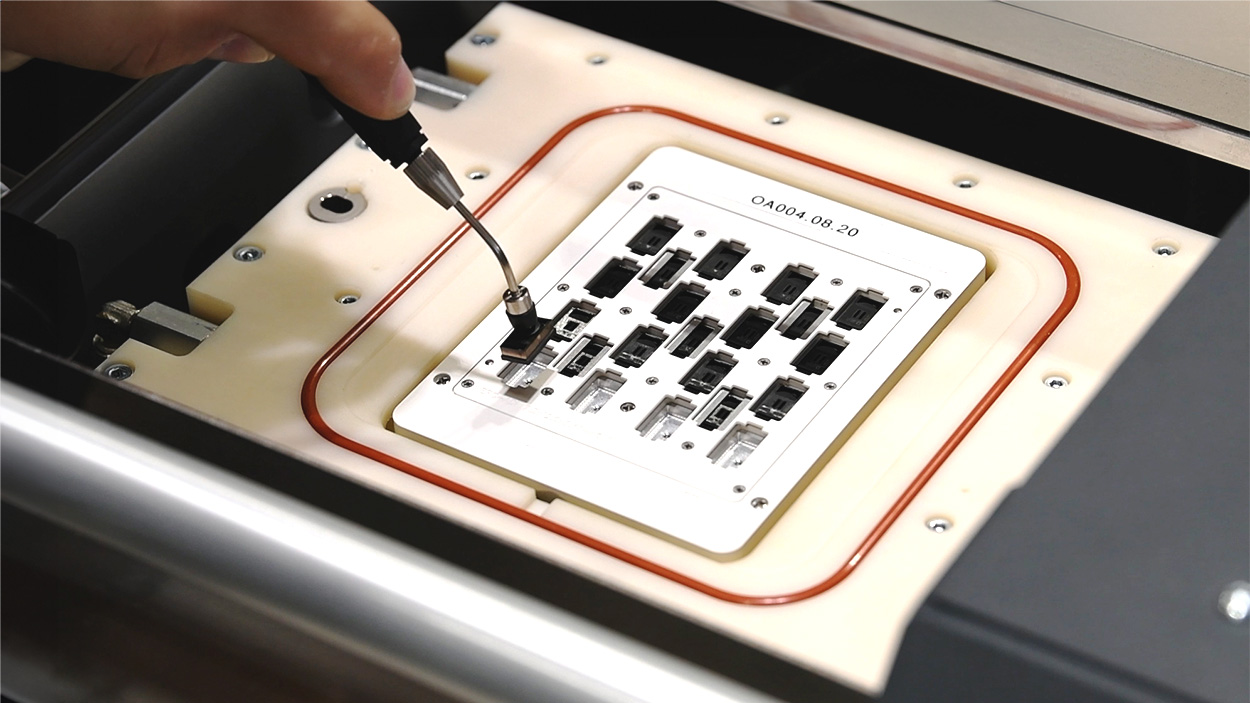

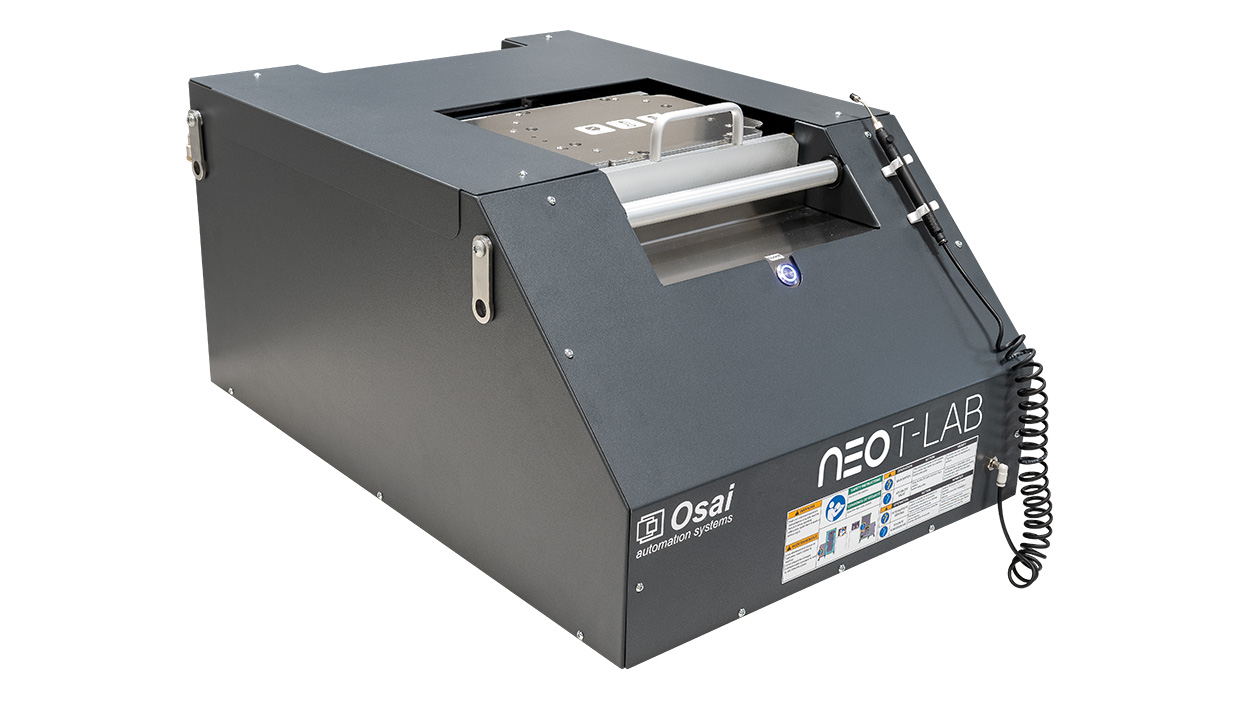

Lab-scale solutions for MEMS sensors testing

Neo T-LAB benchtop series is the OSAI’s ultimate lab test solution for MEMS sensors.

With its compact size Neo T-LAB is the smallest laboratory equipment for products development, characterization and validation.

The possibility to re-use the test hardware (conversion kit) directly to the production test handler dramatically reduces the product’s development costs.

Lab-scale solutions for MEMS sensors testing

Neo T-LAB benchtop series is the OSAI’s ultimate lab test solution for MEMS sensors.

With its compact size Neo T-LAB is the smallest laboratory equipment for products development, characterization and validation.

The possibility to re-use the test hardware (conversion kit) directly to the production test handler dramatically reduces the product’s development costs.