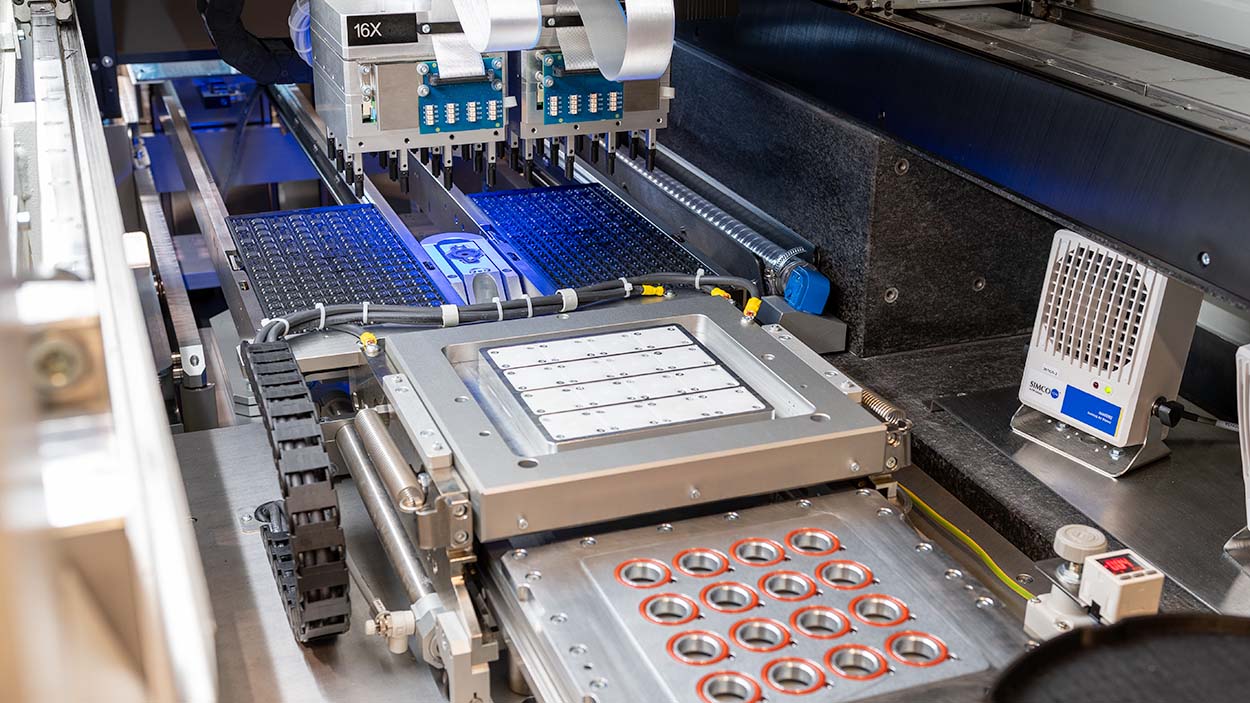

Mass Production Test Handler for MEMS

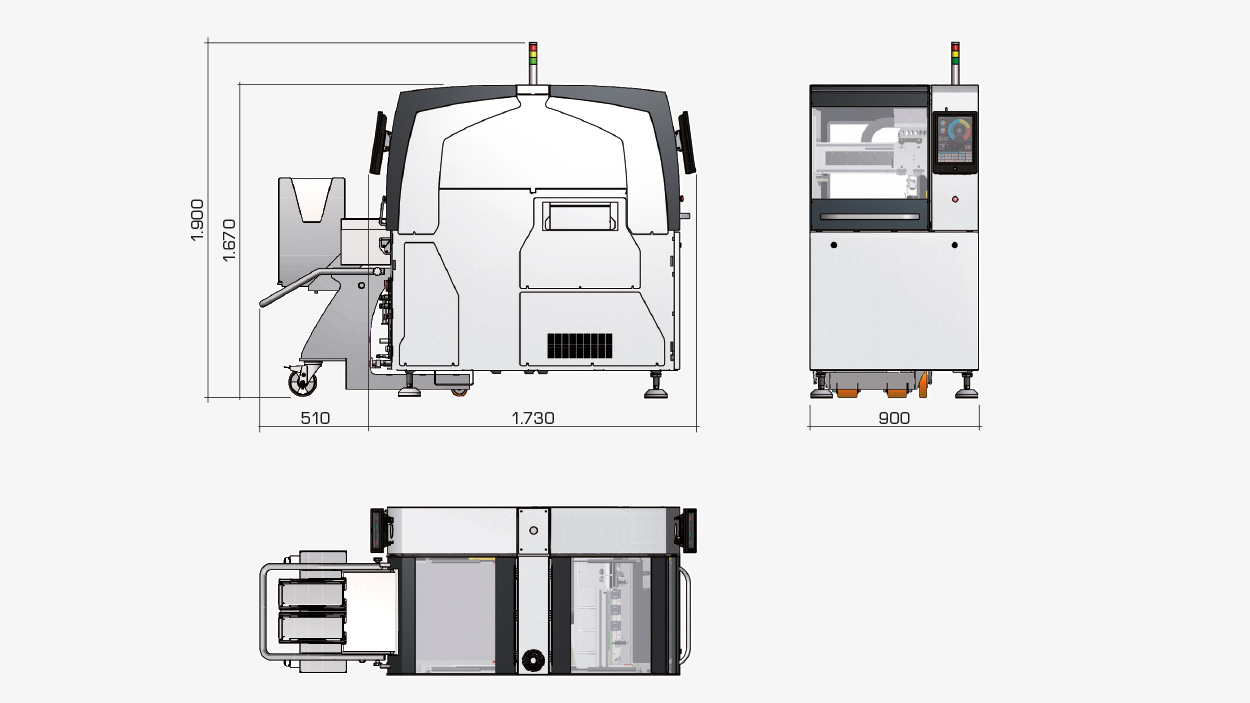

Neo Handler is the first class OSAI equipment for testing Semiconductor MEMS Sensors components. The small footprint (900 x 1600mm) and a scalable architecture allow to dramatically reduce the cost of test.

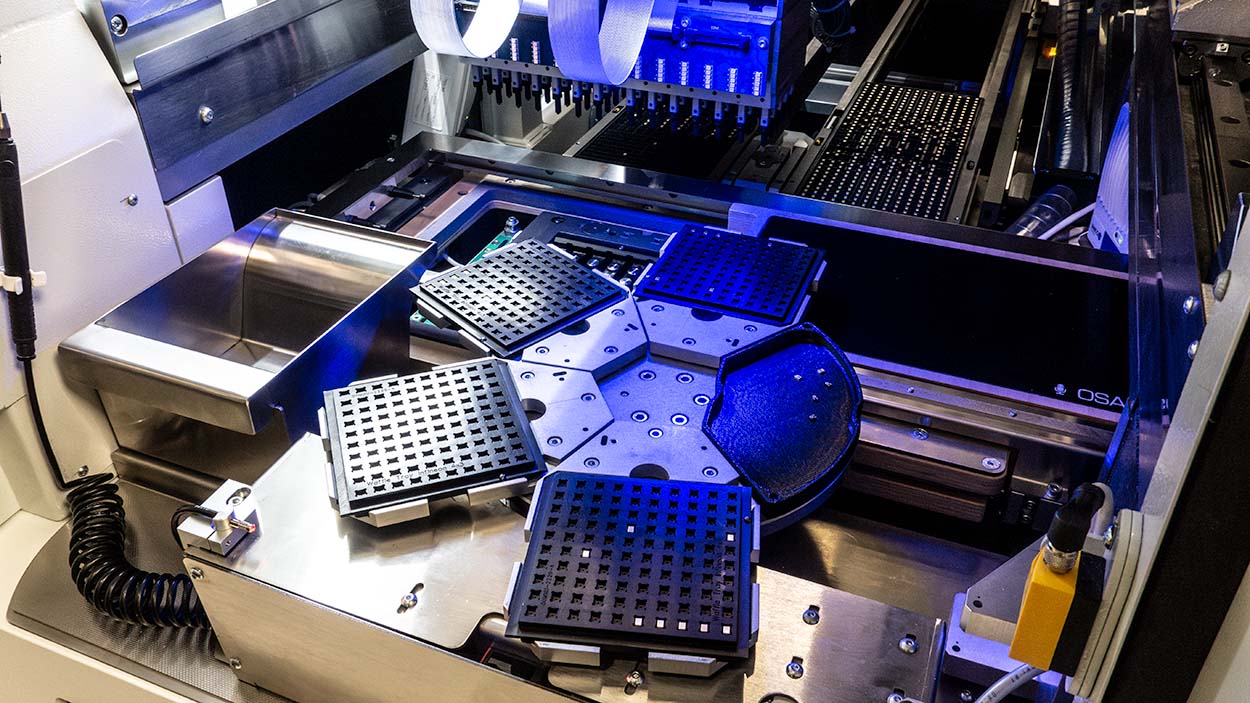

High flexibility, in addition to several combination of I/O feeding (from Direct die to tube feeding), offer an hi-end test handler solution with low operative and investment costs.

The wide range of scalability features offered in OSAI equipment configuration range:

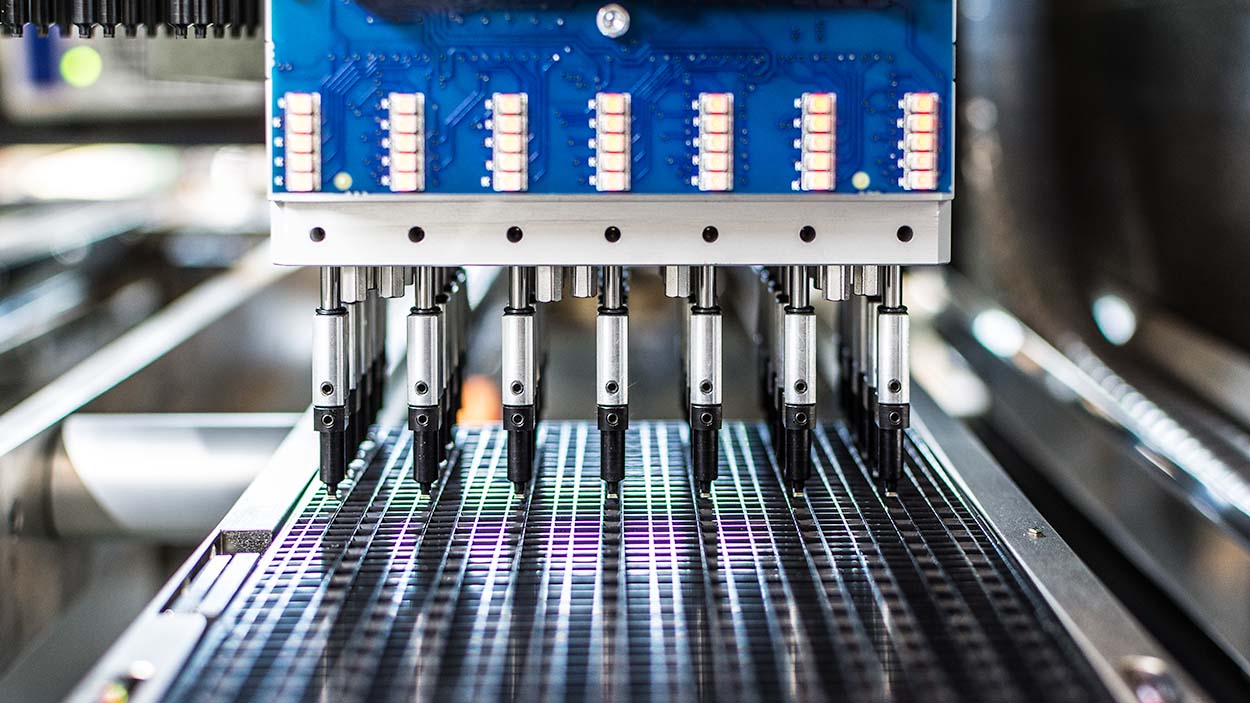

- Multi sites test socket (up to 140 sites)

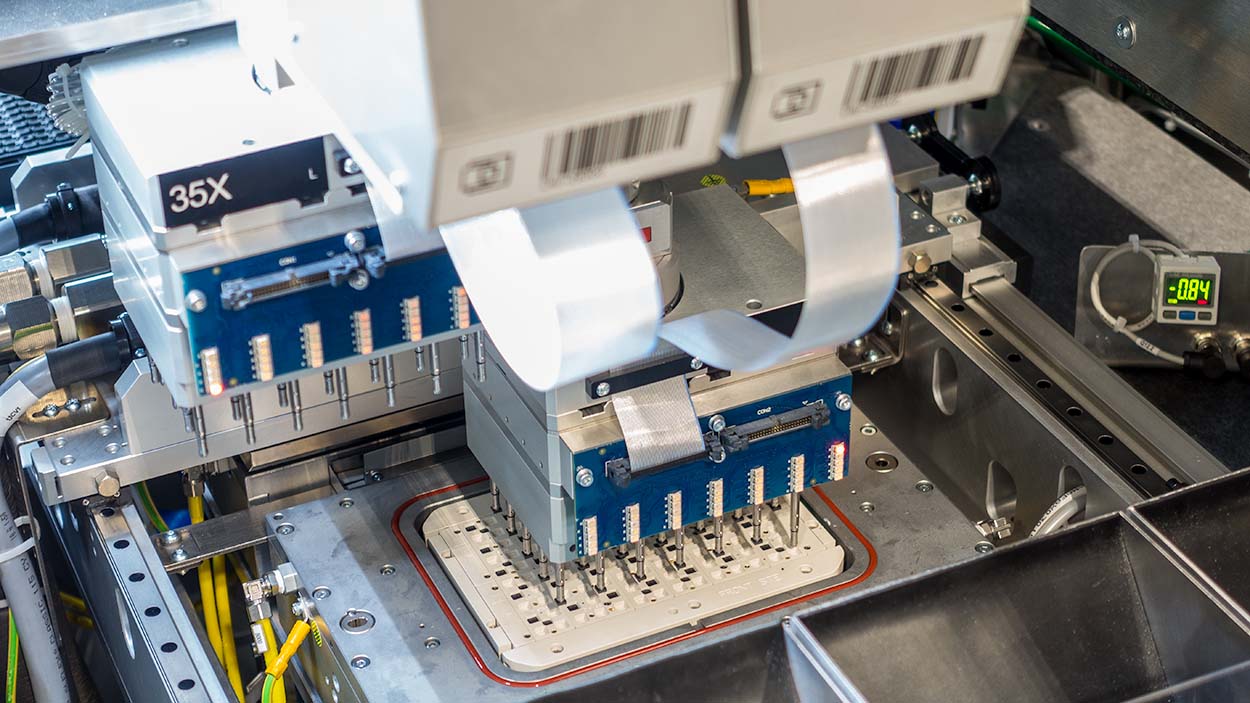

- Multi sites pick up tools (up to 35 sites)

- Stimuli units (Pressure, GAS, Temperature, Humidity, Microphones, Magnetic, Inertial)

Entirely developed by OSAI, Neo Handler can test several MEMS sensors types and geometries.

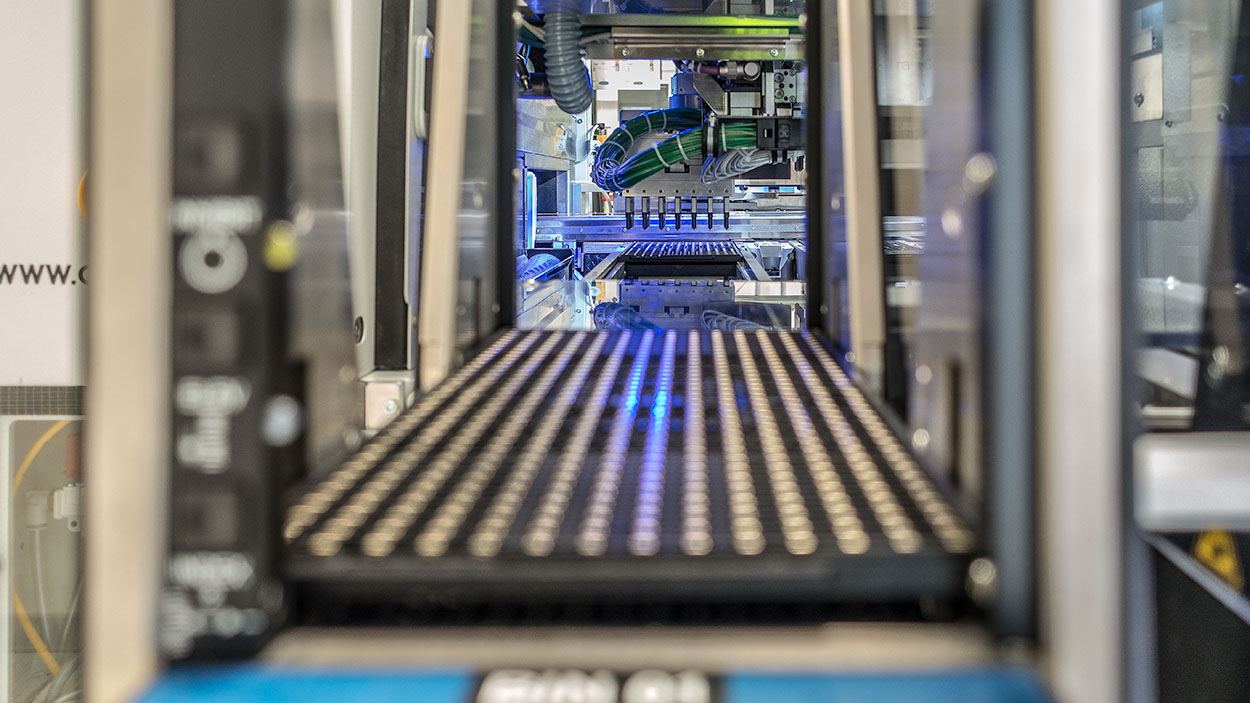

Mass Production Test Handler for MEMS

Neo Handler is the first class OSAI equipment for testing Semiconductor MEMS Sensors components. The small footprint (900 x 1600mm) and a scalable architecture allow to dramatically reduce the cost of test.

High flexibility, in addition to several combination of I/O feeding (from Direct die to tube feeding), offer an hi-end test handler solution with low operative and investment costs.

The wide range of scalability features offered in OSAI equipment configuration range:

- Multi sites test socket (up to 140 sites)

- Multi sites pick up tools (up to 35 sites)

- Stimuli units (Pressure, GAS, Temperature, Humidity, Microphones, Magnetic, Inertial)

Entirely developed by OSAI, Neo Handler can test several MEMS sensors types and geometries.