Solutions for Power Devices Production

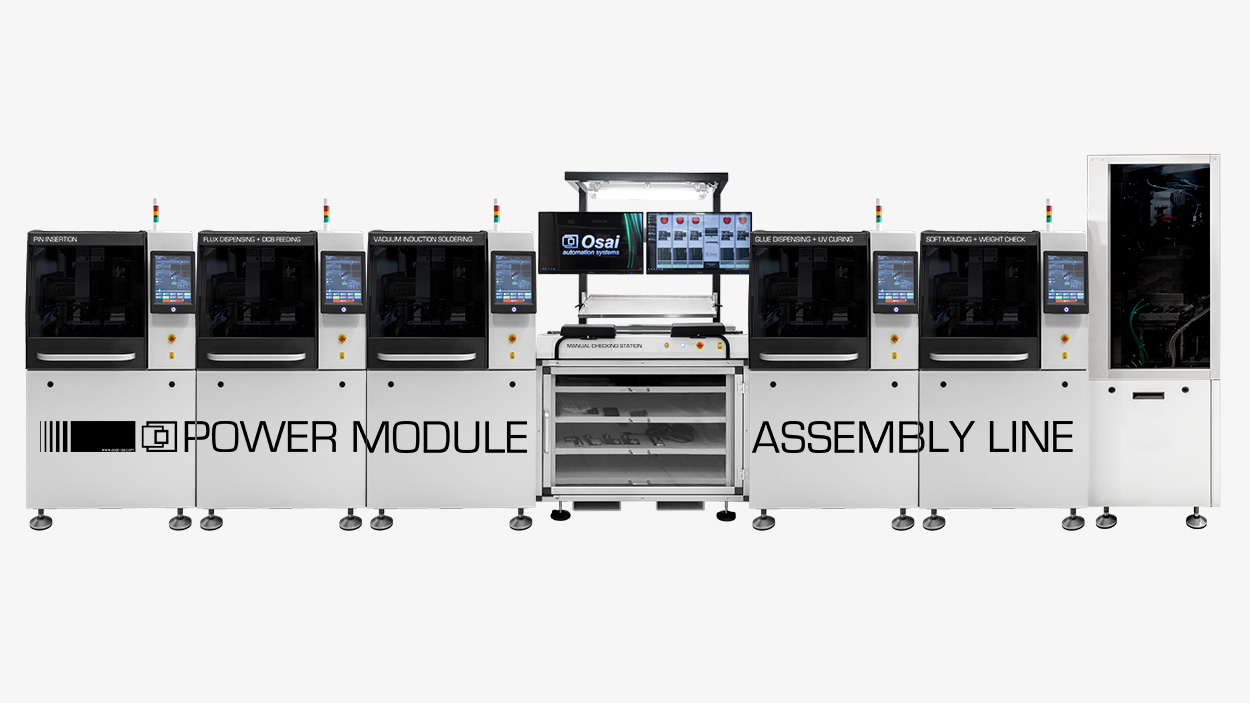

Power Module Assembly Line is an investment for the future. Osai experience in semiconductor application automation can make the mass production easy, reliable and 100% human error free.

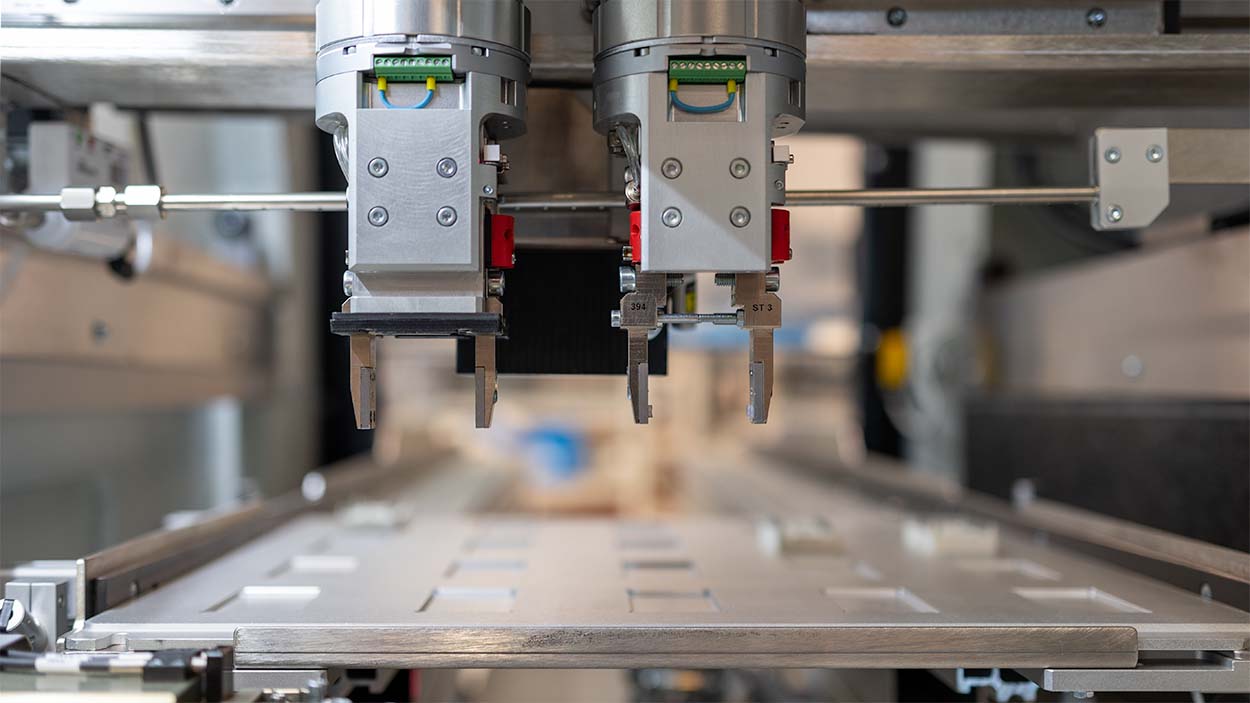

This equipment is used to assemble different parts of power modules such as dice, lead frame, preform, and plastic case.

Suitable for: Dice, Preform, AMB, Lead Frame, Plastic Case

Configurable Input Media: Tray, Blister, Tape & Reel, Bulk, Film Frame

High Accuracy: ±5ym

High Speed: Up to 1sec/cycle

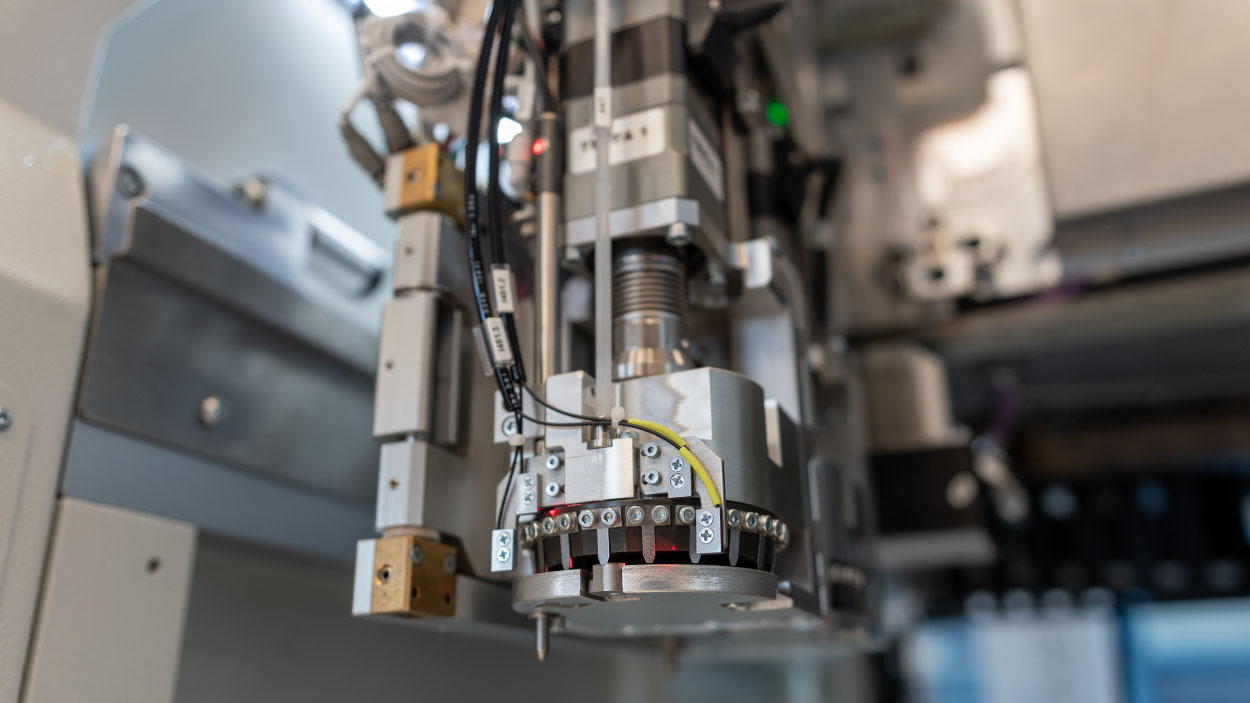

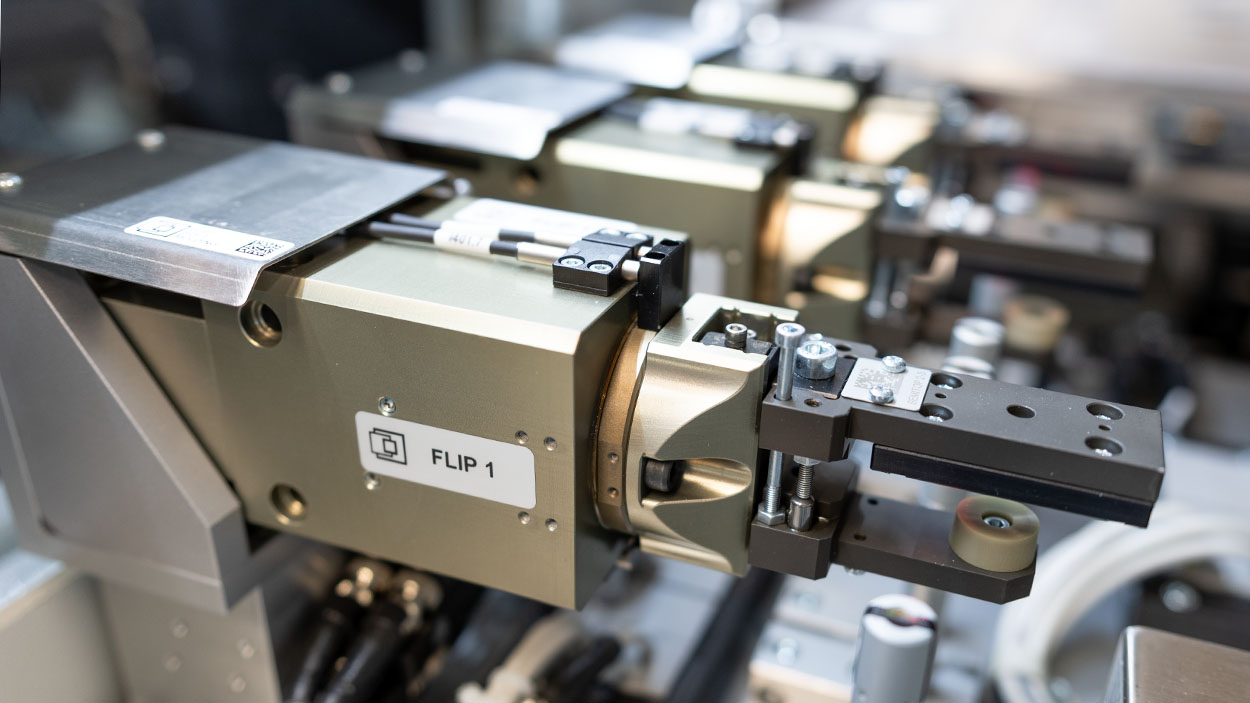

This equipment is used to place the pins of the substrate. It works for both wired (inserted) and coil pins (punched and soldered in the next phase)

Suitable for: Wired Pins and Coil Pins

High Accuracy: ±5ym

Pin Insertion Check: Height ±50ym, Force Control up to 500N

High Speed: Up to 2pins/s

Optical Features: Single Pin Optical Alignement, 3D Scan Check

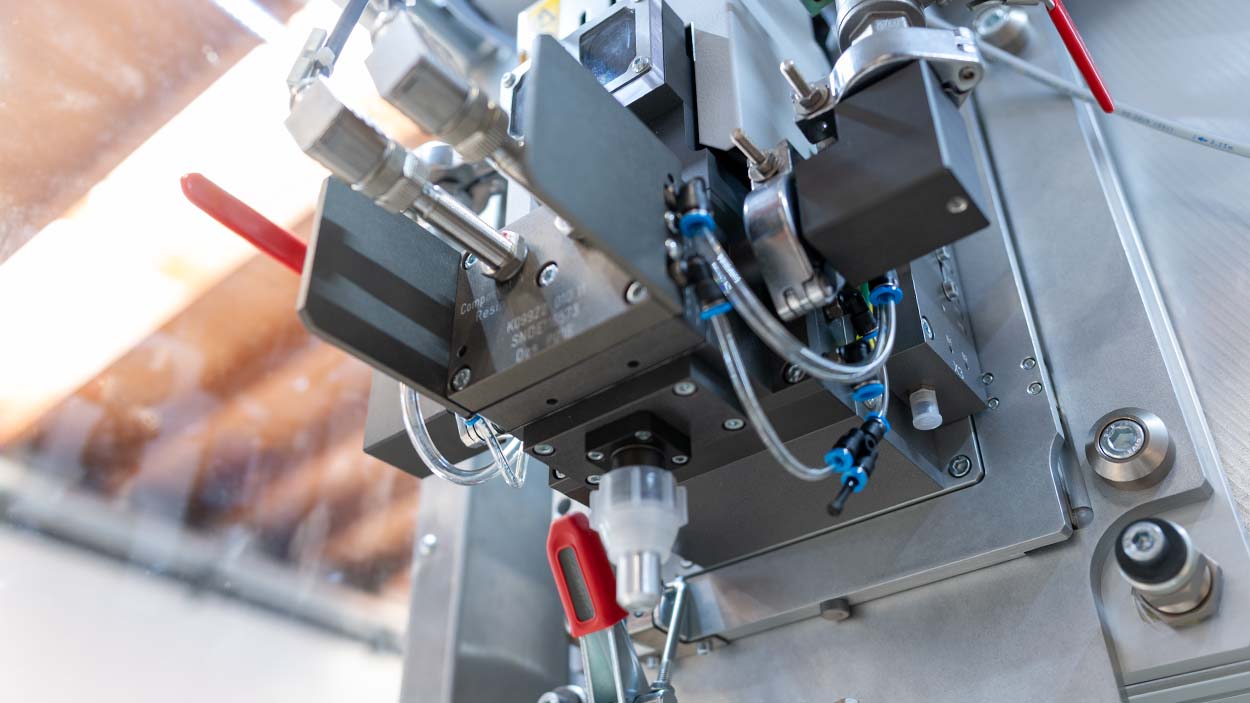

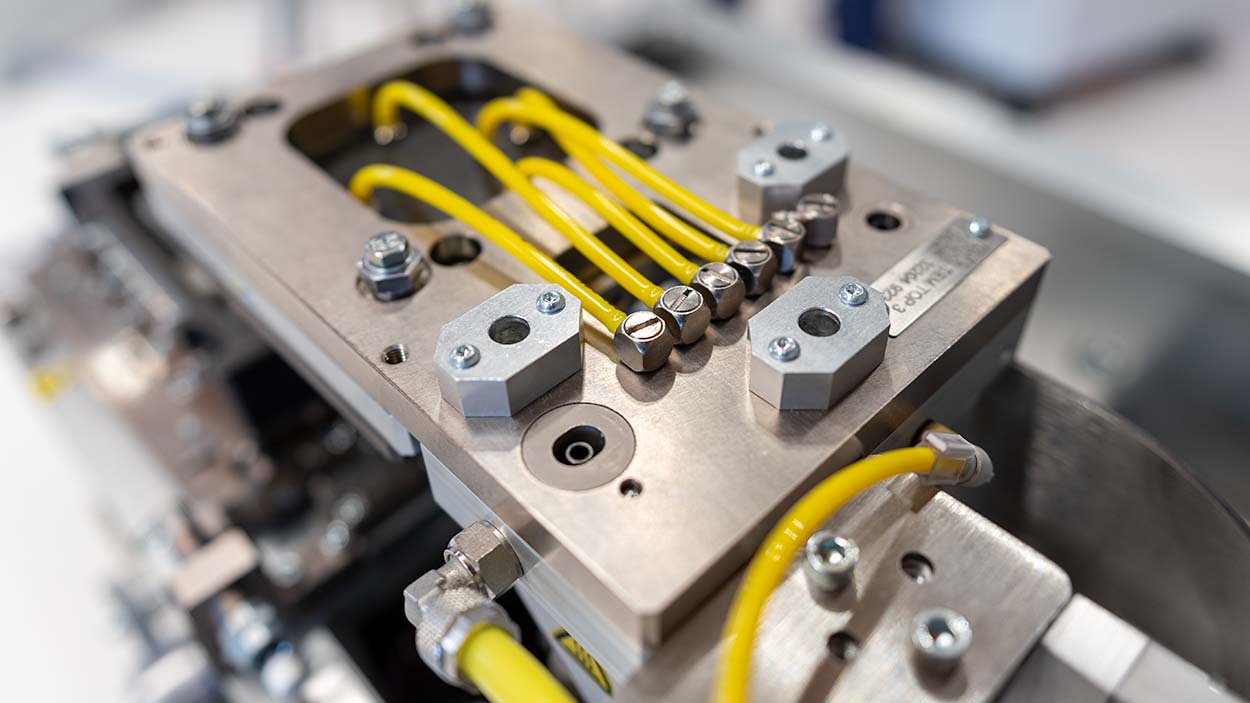

This equipment can be configured with: glue, flux jet dispenser (with integrated optical check and UV curing) or SilGel dispenser (teo components volumetric dispenser) with vacuum potting chamber

Suitable for: Ultra Fast Jet Dispensing/Two Components Volumetric Dispensing

Designed for: Flux, Glue, SilGel

High Accuracy: ±5ym

Optical Features: UV Lighting Vision System, Long Life LED UV Curing

High Speed: Up to 300PH

Additional Features: Vacuum Potting Chamber, Weight Check

According to the connection method, the equipment can be configured to perform Vacuum induction soldering or ultrasonic welding

Suitable for: Lead Frame Welding / Pin Soldering

High Accuracy: ±5ym

Top Notch Technology: Linear or Torsional Ultrasonic Welding, Patented Vacuum Induction Soldering

Optical Features: Full Optical Alignement, Quality Optical Inspection

This equipment is used to mark every single leadframe/AMB, and device, to allow each single unit traceability. The green Laser sources is the ultimate solution for a fast, and accurate marking on copper, silver, ceramic substrate and plastic case

LASER: Green

Fiducial Check: For accurate marking position

100% Data and Grading Check: On 1d/2d code

Optical Check: For component presence/absence

Full Library: 2D code, Bar code, QR code and others

Tailored DB Communication: For traceability

Key points

Standard/customized automation solution

Power modules packages compliant

High productivity

for mass production

Complete monolithic production lines

Built-in Predictive maintenance

AGV

ready

Secs-GEM

ready

Solutions for Power Devices Production

Power Module Assembly Line is an investment for the future. Osai experience in semiconductor application automation can make the mass production easy, reliable and 100% human error free.

This equipment is used to assemble different parts of power modules such as dice, lead frame, preform, and plastic case.

Suitable for: Dice, Preform, AMB, Lead Frame, Plastic Case

Configurable Input Media: Tray, Blister, Tape & Reel, Bulk, Film Frame

High Accuracy: ±5ym

High Speed: Up to 1sec/cycle

This equipment is used to place the pins of the substrate. It works for both wired (inserted) and coil pins (punched and soldered in the next phase)

Suitable for: Wired Pins and Coil Pins

High Accuracy: ±5ym

Pin Insertion Check: Height ±50ym, Force Control up to 500N

High Speed: Up to 2pins/s

Optical Features: Single Pin Optical Alignement, 3D Scan Check

This equipment can be configured with: glue, flux jet dispenser (with integrated optical check and UV curing) or SilGel dispenser (teo components volumetric dispenser) with vacuum potting chamber

Suitable for: Ultra Fast Jet Dispensing/Two Components Volumetric Dispensing

Designed for: Flux, Glue, SilGel

High Accuracy: ±5ym

Optical Features: UV Lighting Vision System, Long Life LED UV Curing

High Speed: Up to 300PH

Additional Features: Vacuum Potting Chamber, Weight Check

According to the connection method, the equipment can be configured to perform Vacuum induction soldering or ultrasonic welding

Suitable for: Lead Frame Welding / Pin Soldering

High Accuracy: ±5ym

Top Notch Technology: Linear or Torsional Ultrasonic Welding, Patented Vacuum Induction Soldering

Optical Features: Full Optical Alignement, Quality Optical Inspection

This equipment is used to mark every single leadframe/AMB, and device, to allow each single unit traceability. The green Laser sources is the ultimate solution for a fast, and accurate marking on copper, silver, ceramic substrate and plastic case

LASER: Green

Fiducial Check: For accurate marking position

100% Data and Grading Check: On 1d/2d code

Optical Check: For component presence/absence

Full Library: 2D code, Bar code, QR code and others

Tailored DB Communication: For traceability

Key points

Standard/customized automation solution

Power modules packages compliant

High productivity

for mass production

Complete monolithic production lines

Built-in Predictive maintenance

AGV

ready

Secs-GEM

ready