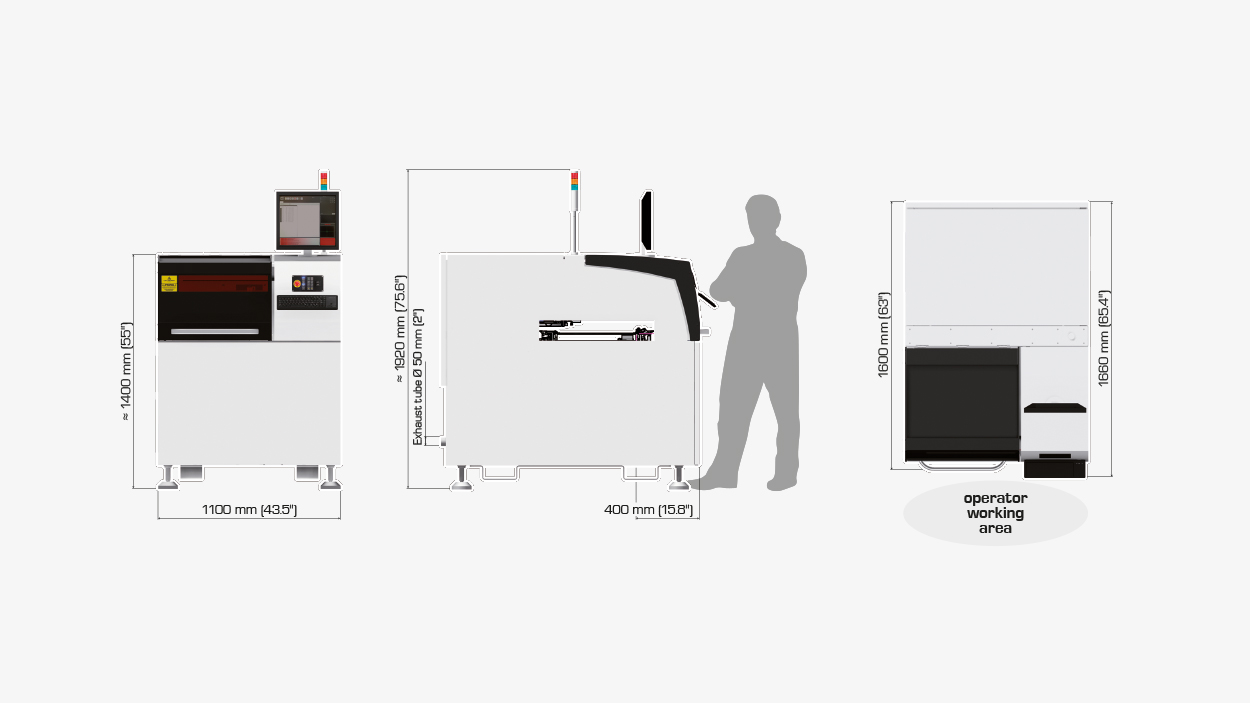

Laser Depaneling for special substrates and applications

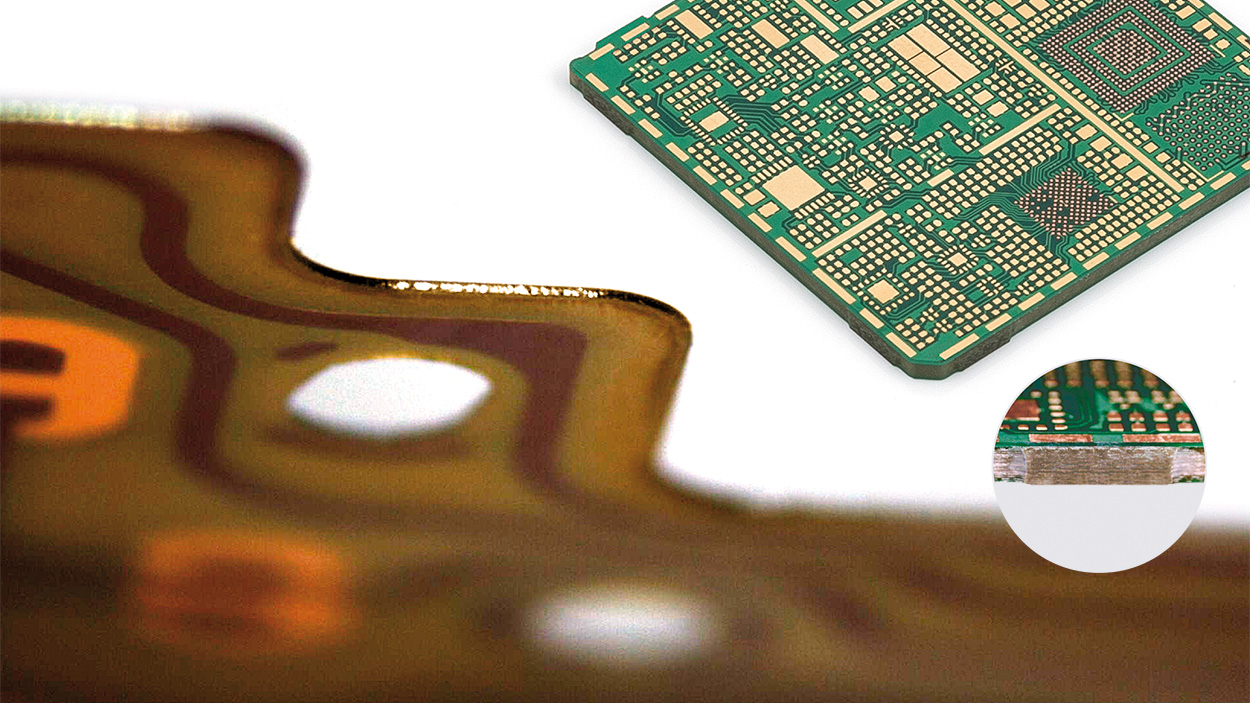

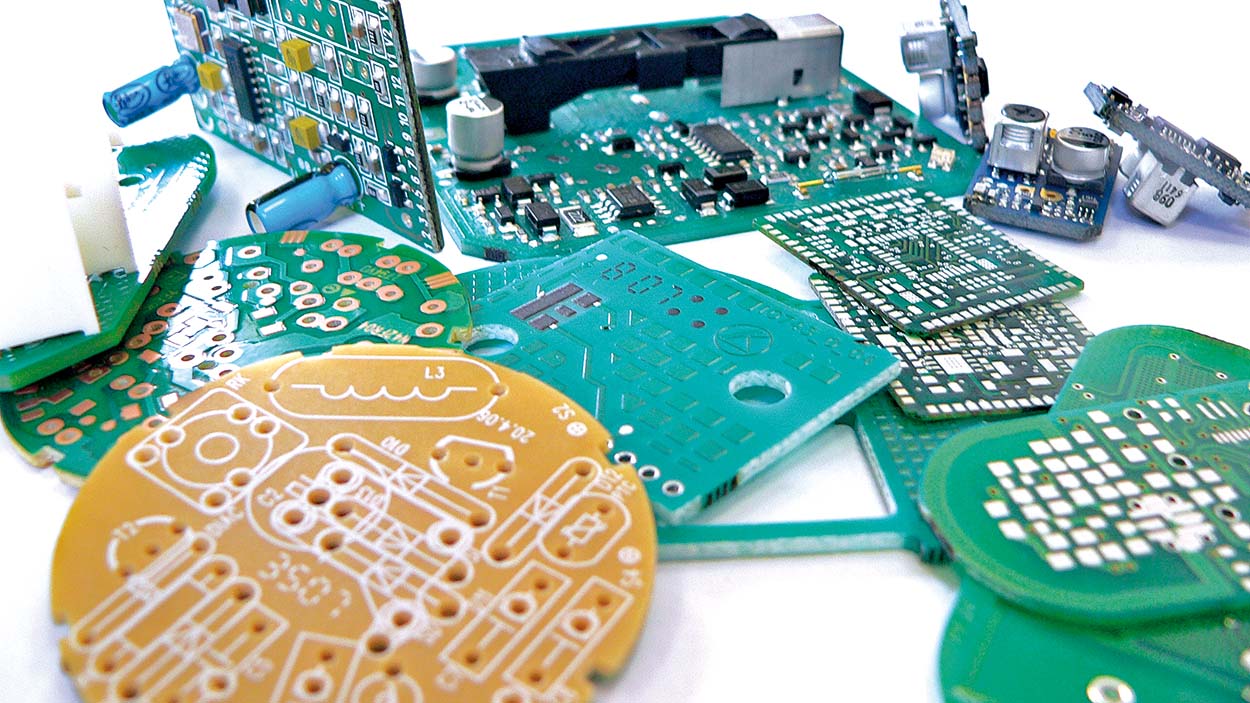

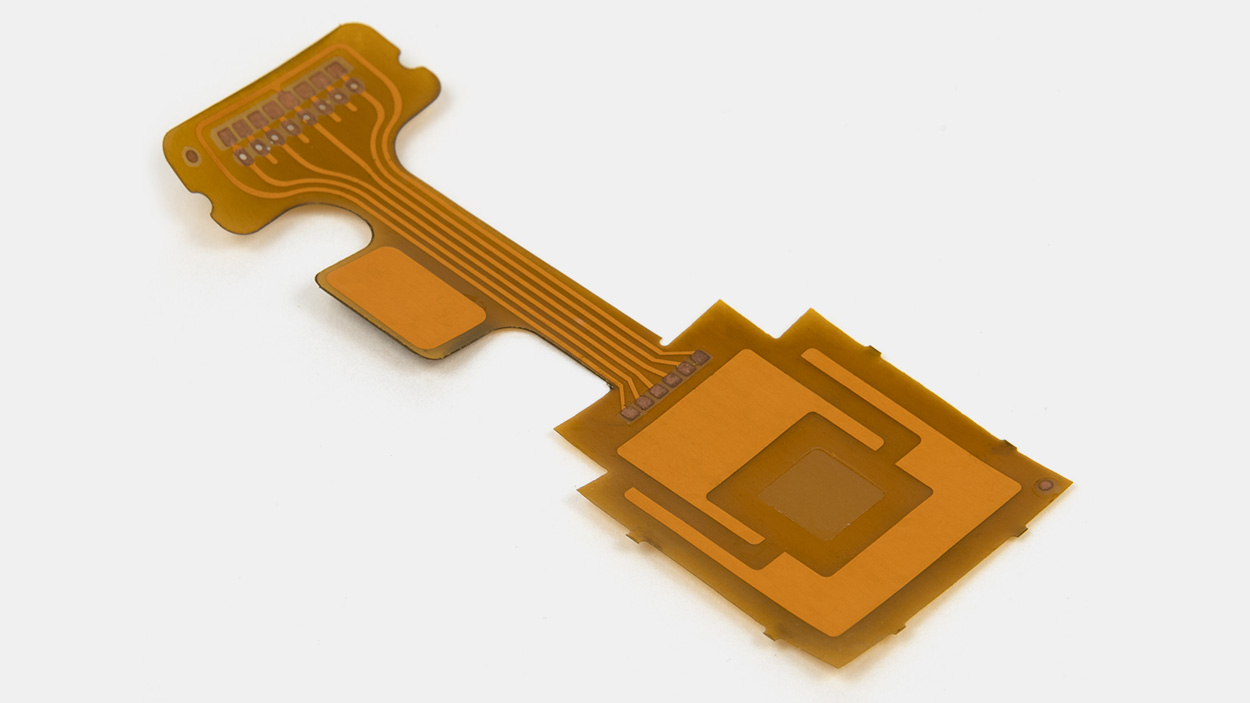

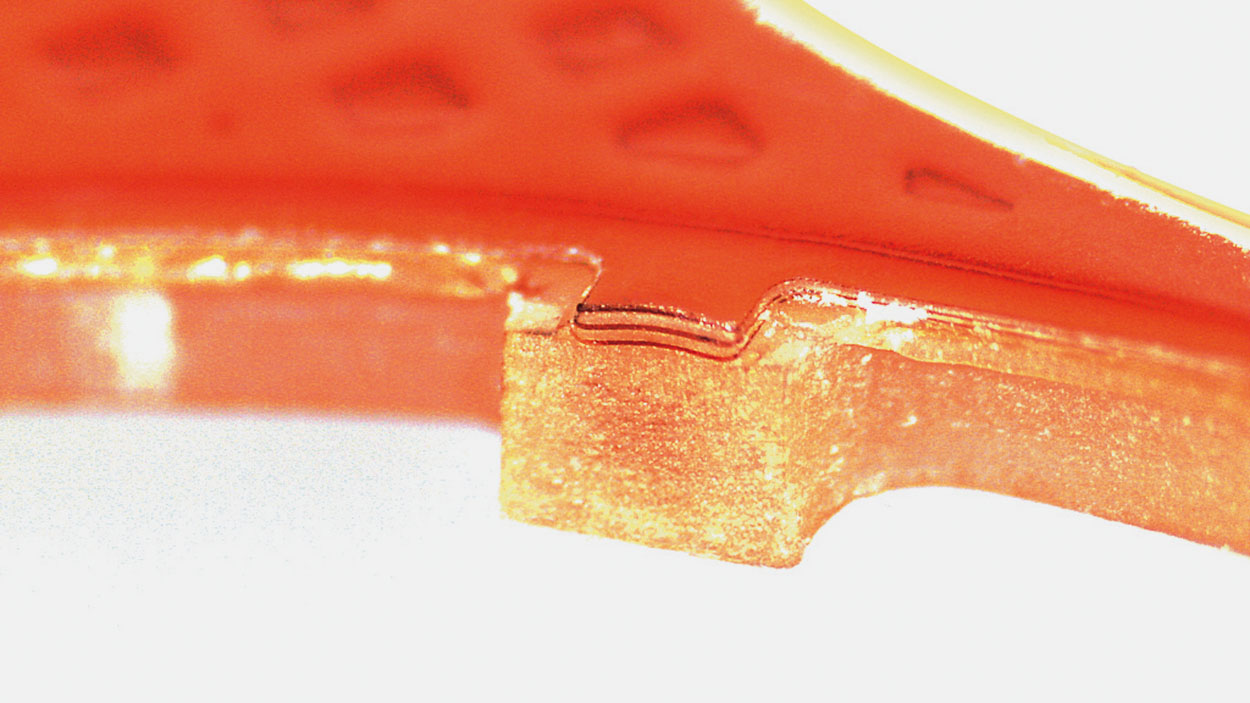

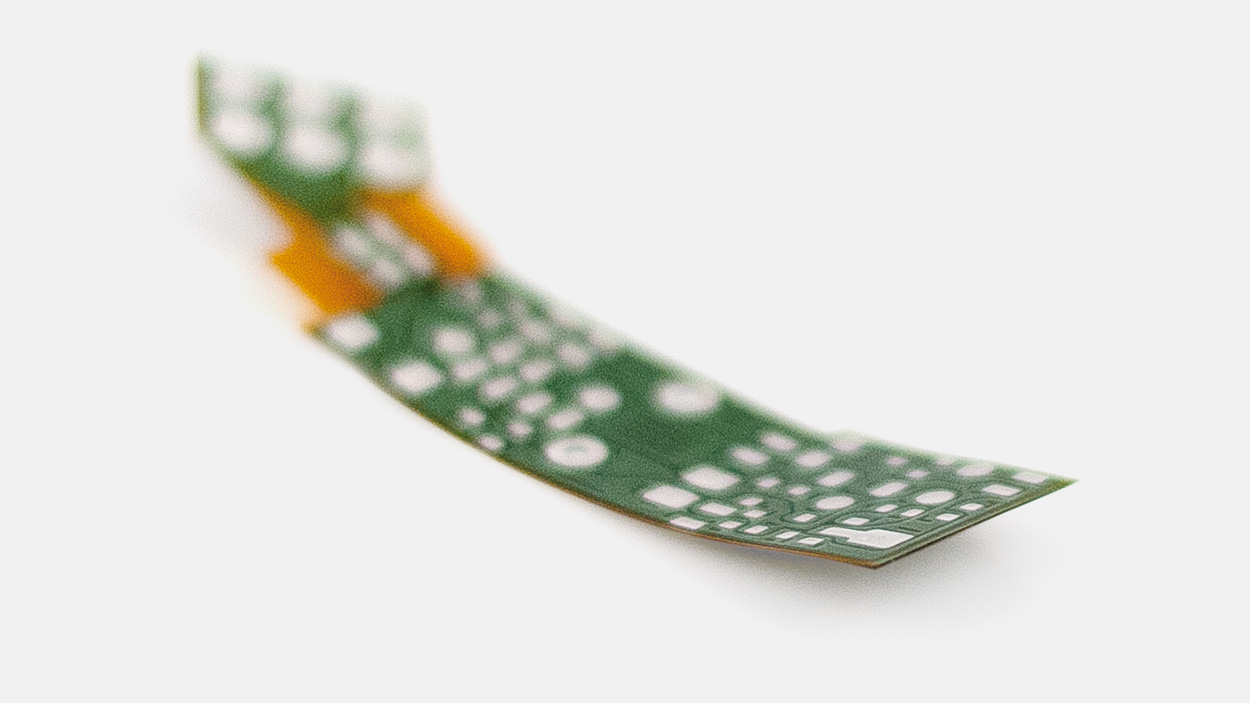

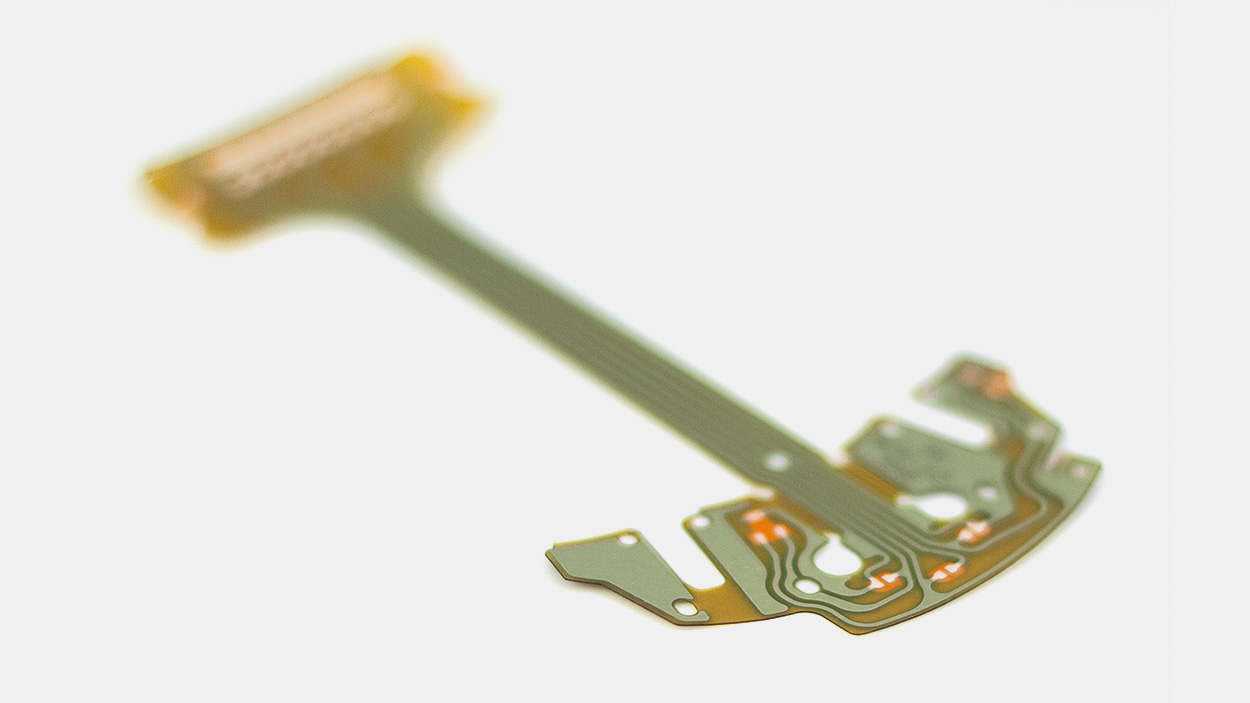

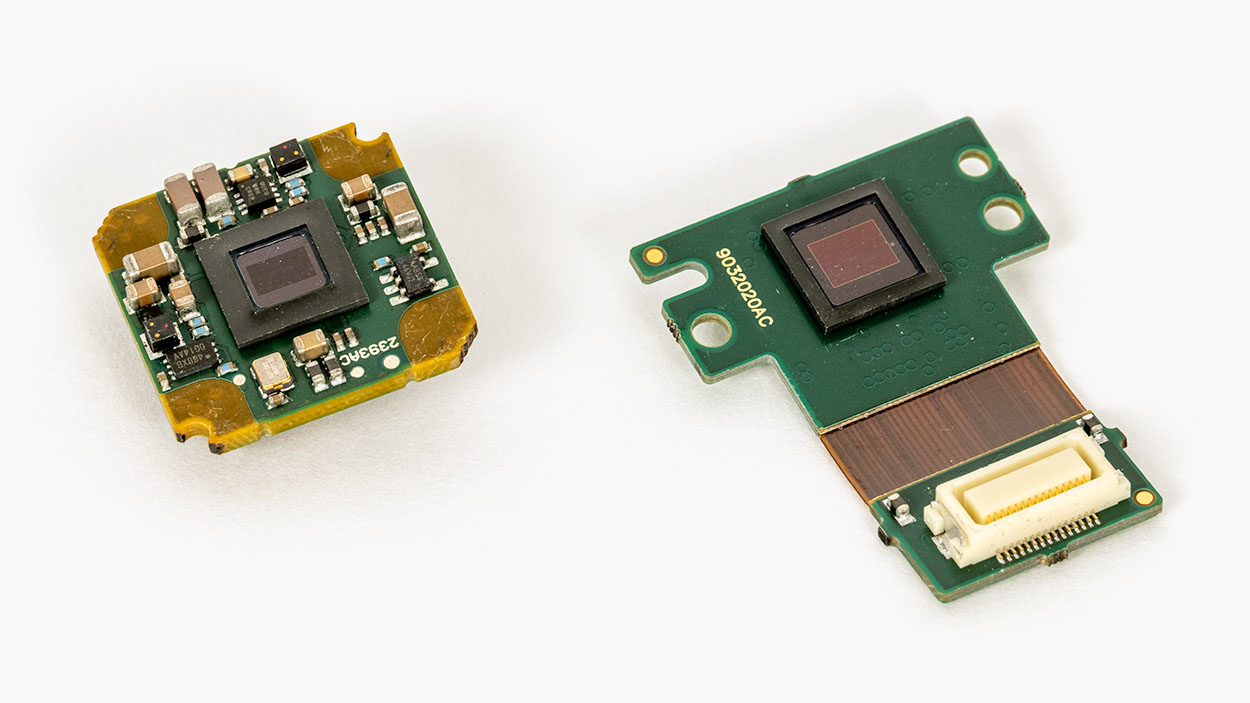

NeoCut Shape is the solution for Laser cutting of electronic boards and special materials. The wide range of available Laser sources allows the cutting of rigid and flexible boards (UV or Green Lasers are suitable for FR4 and Kapton), as well as special materials such as ceramics and alumina, which are instead wrought with an Ultrafast Pico Laser infrared source. This Ultrafast Pico Laser infrared source is also capable of cutting rigid boards (FR4) with zero carbonisation effect.

As with the Neocut Easy, the creation of recipes (cutting programs) for the Neocut Shape can be done manually, by ‘drawing’ the cutting lines directly on the image of the board on the machine screen, or, for greater positioning accuracy, the DXF file of the board can be imported to define the cutting points.

Laser Depaneling for special substrates and applications

NeoCut Shape is the solution for Laser cutting of electronic boards and special materials. The wide range of available Laser sources allows the cutting of rigid and flexible boards (UV or Green Lasers are suitable for FR4 and Kapton), as well as special materials such as ceramics and alumina, which are instead wrought with an Ultrafast Pico Laser infrared source. This Ultrafast Pico Laser infrared source is also capable of cutting rigid boards (FR4) with zero carbonisation effect.

As with the Neocut Easy, the creation of recipes (cutting programs) for the Neocut Shape can be done manually, by ‘drawing’ the cutting lines directly on the image of the board on the machine screen, or, for greater positioning accuracy, the DXF file of the board can be imported to define the cutting points.