Laser Depaneling for FR4 and flexible PCBs

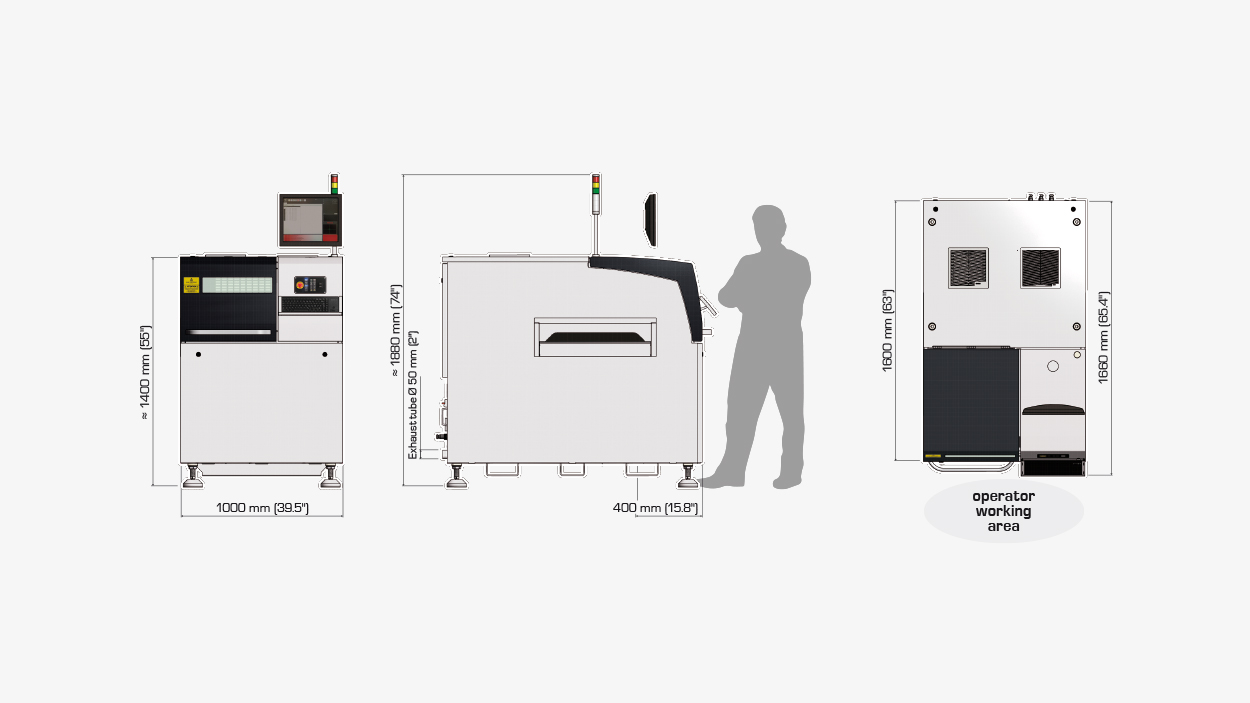

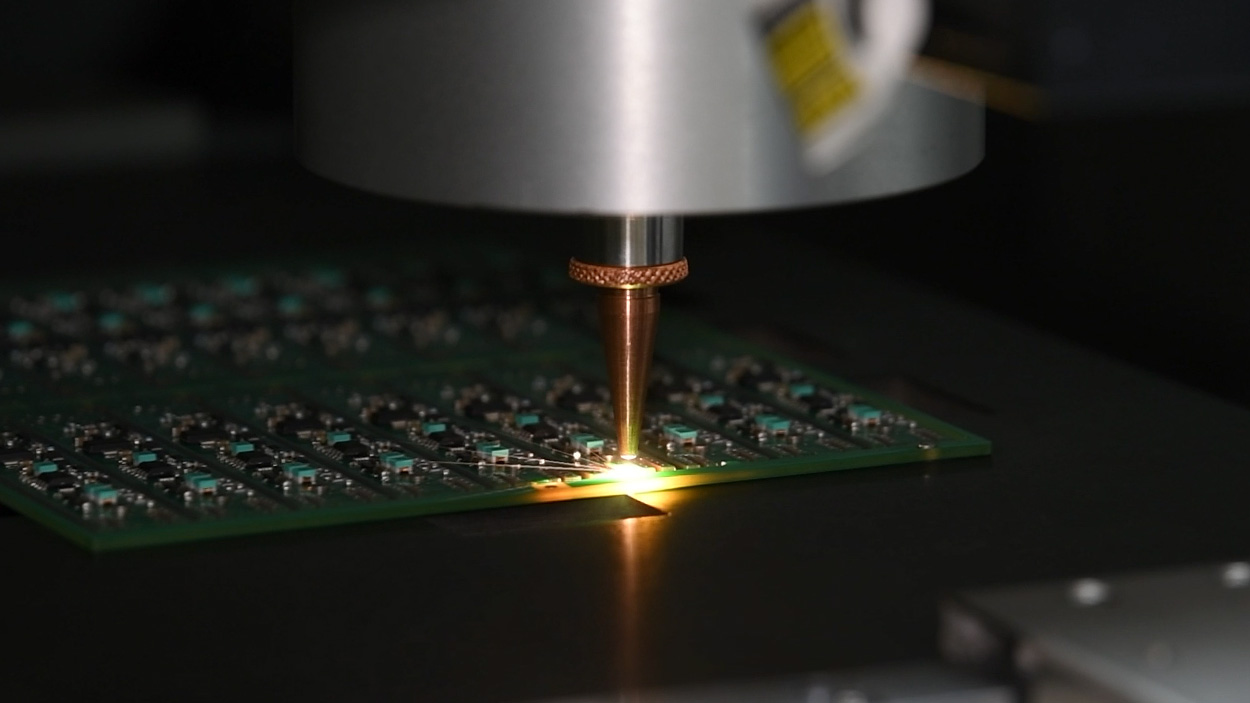

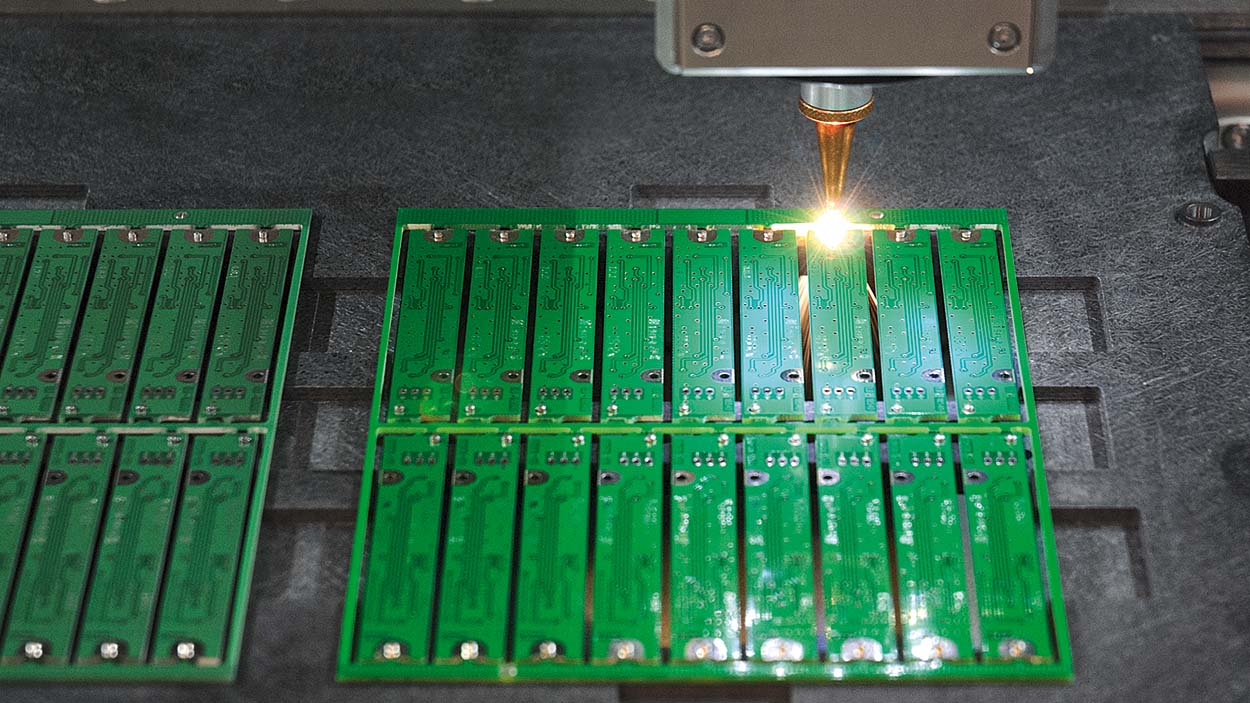

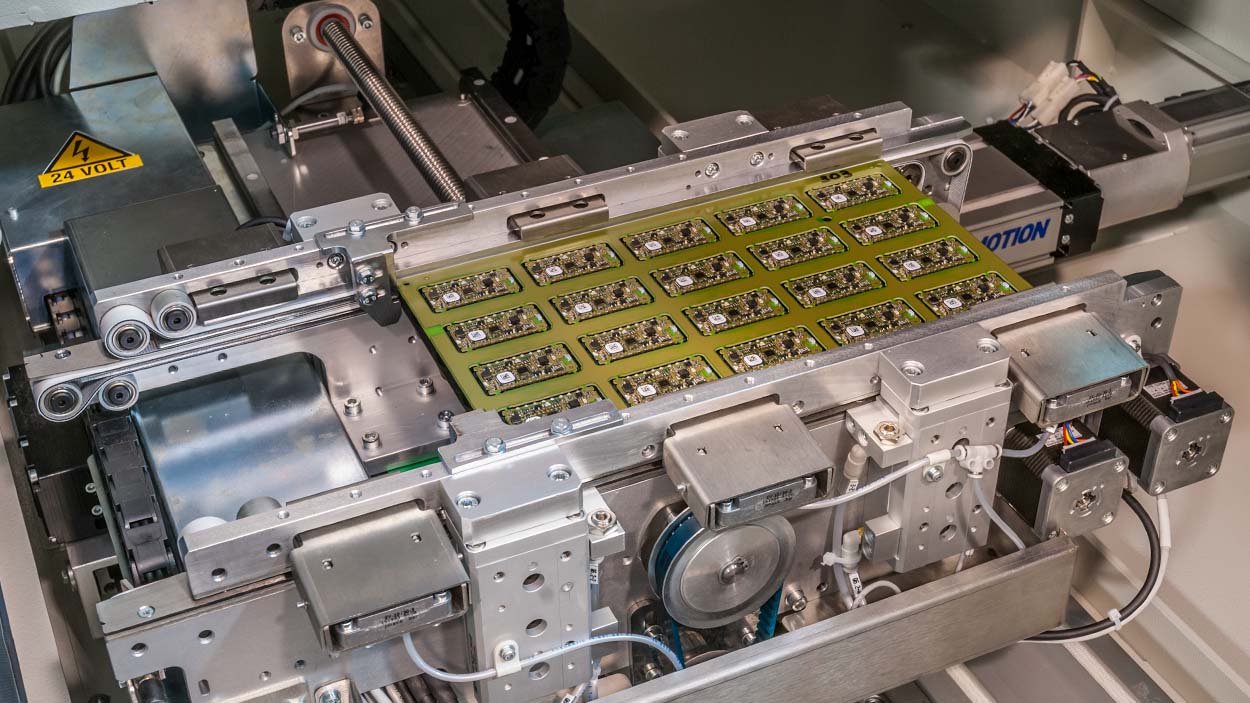

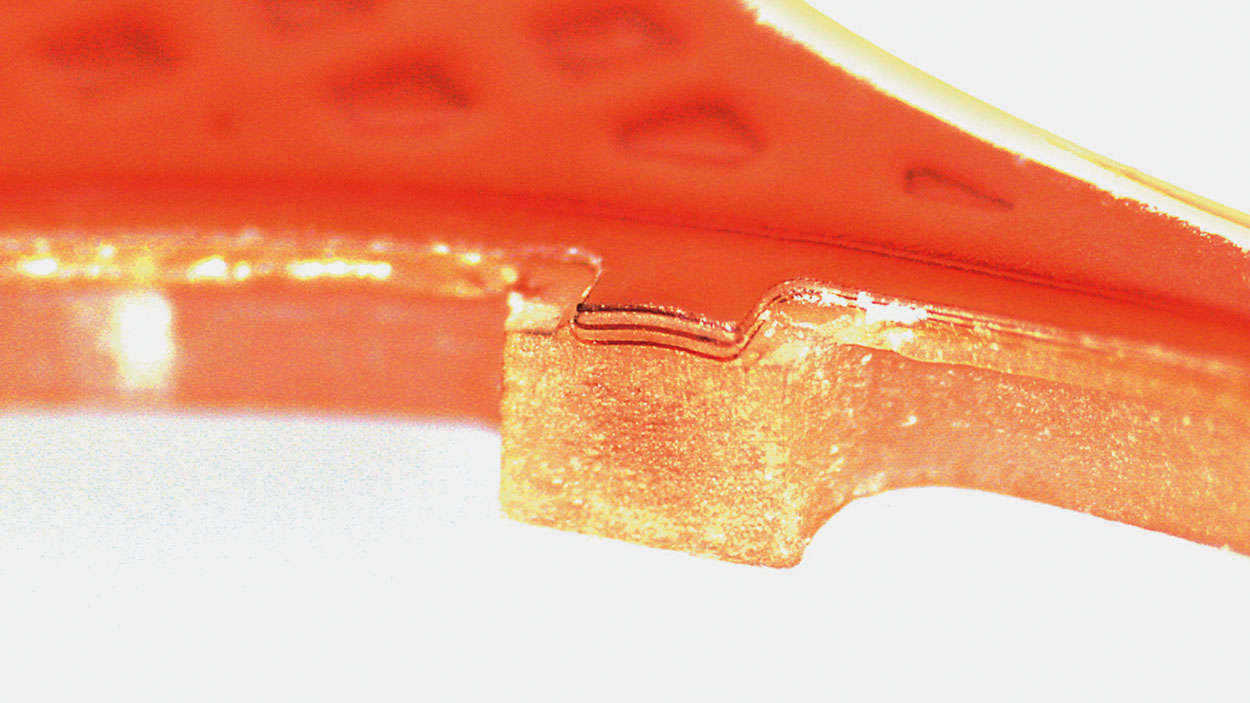

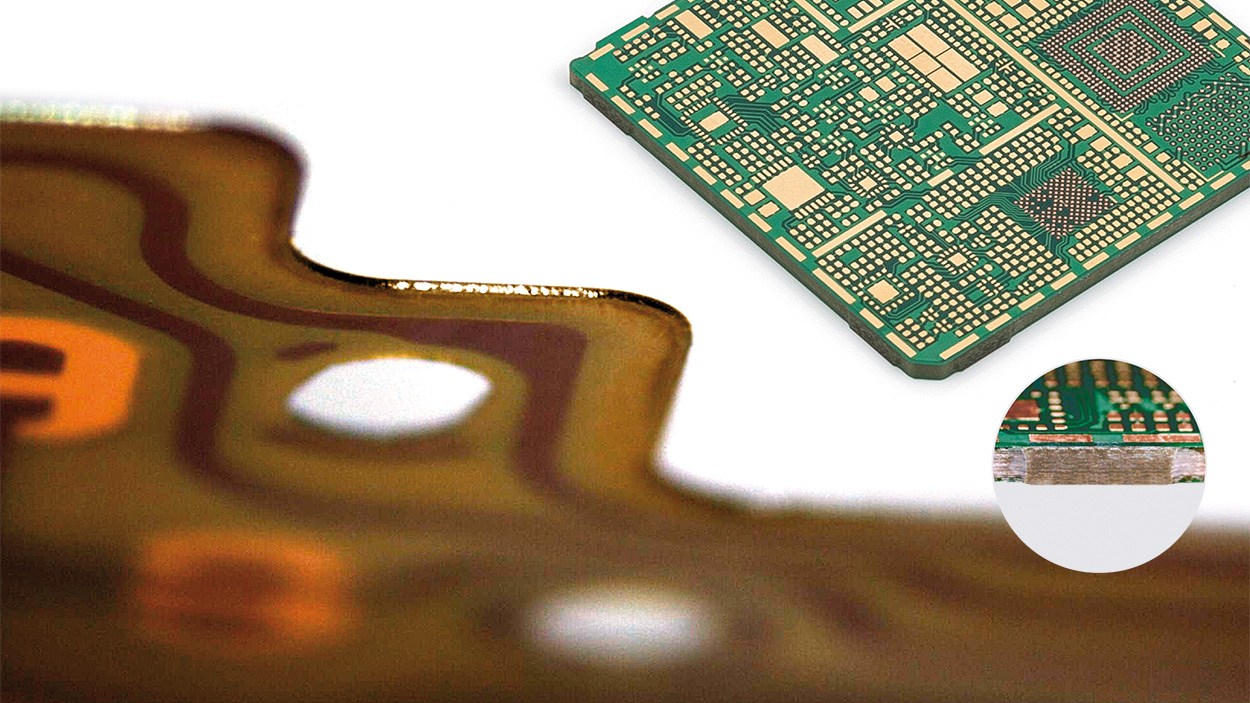

NeoCut Easy is the solution for Laser cutting of electronic boards. Unlike mechanical depaneling processes (conventional router and blade), Laser cutting is the only process that produces no mechanical stress on the board or its components, thus eliminating the risk of cracks on them. Moreover, it is a process that generates no residue.

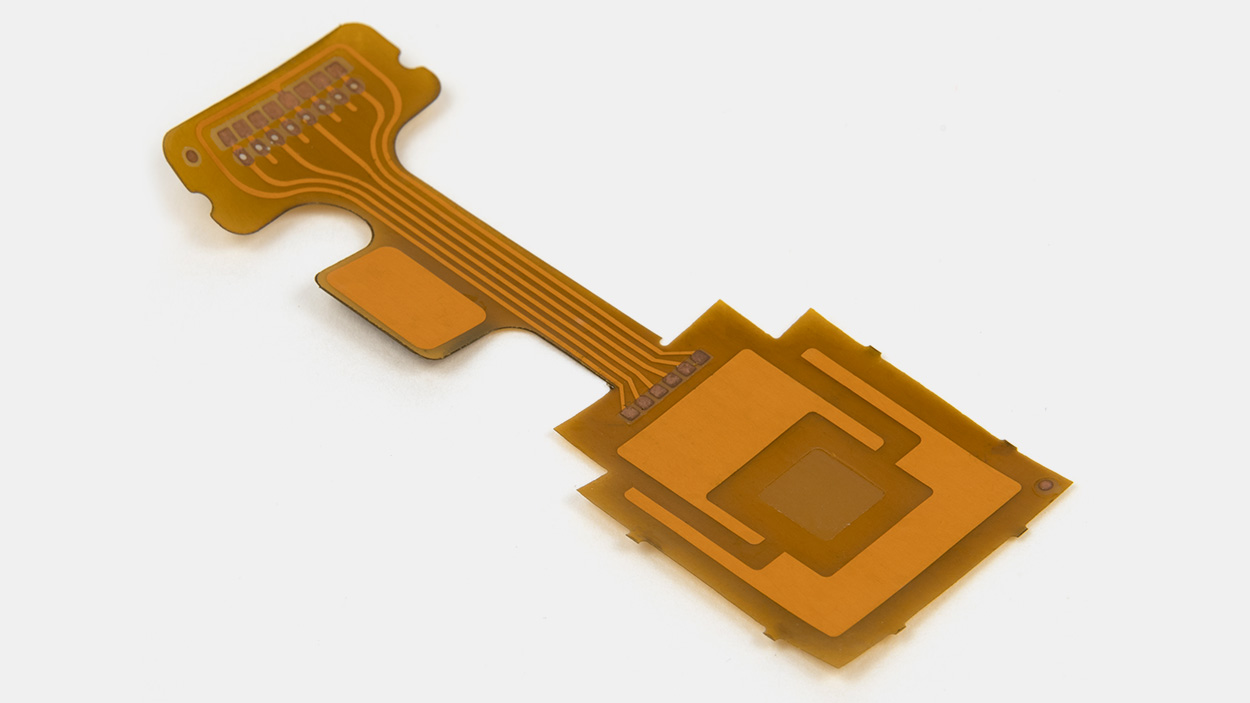

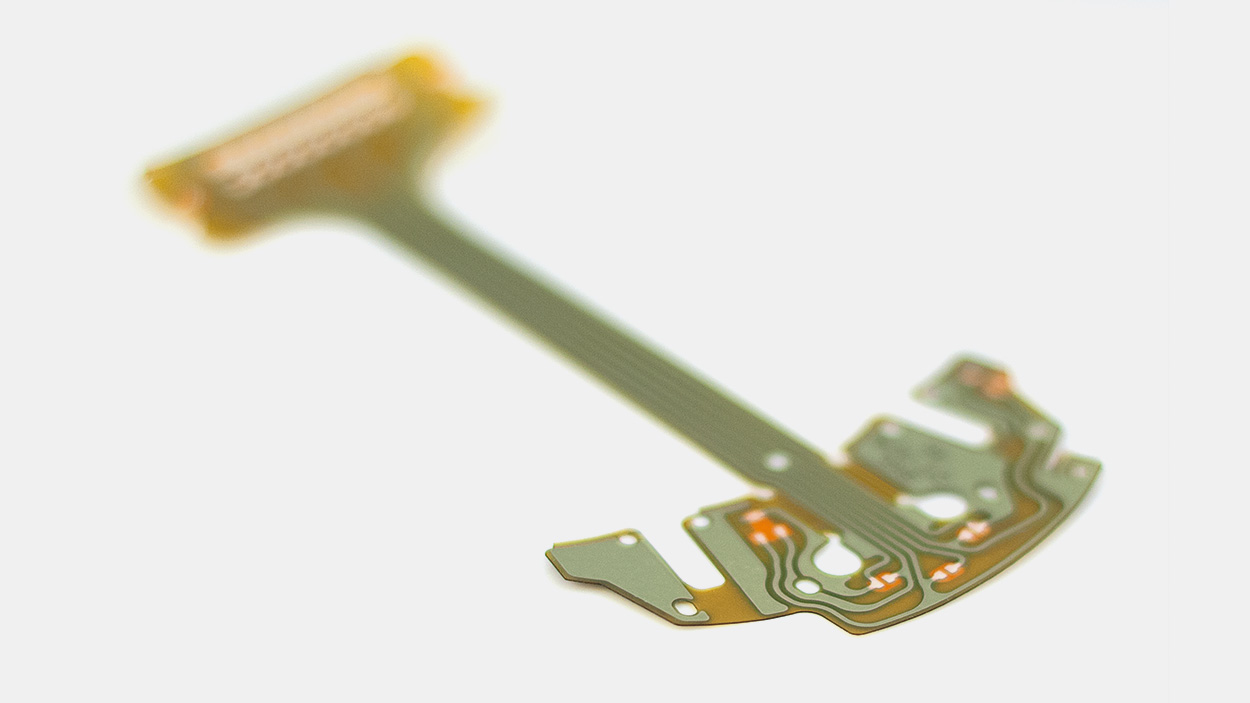

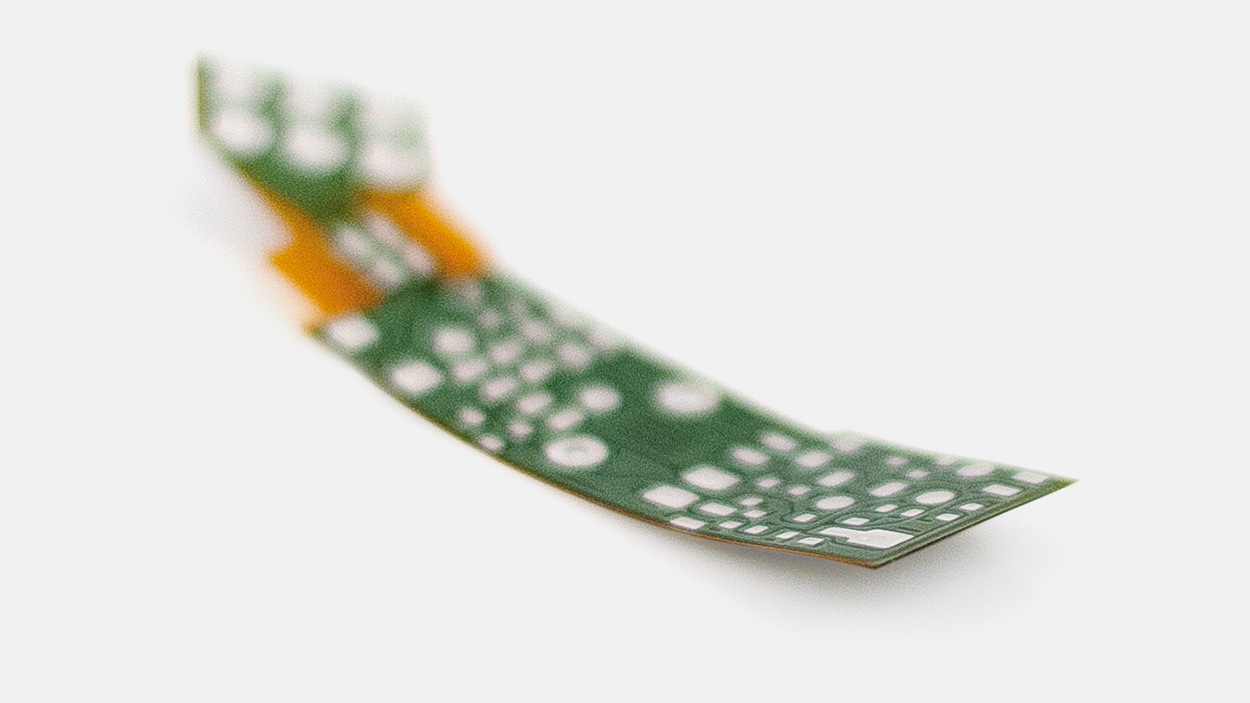

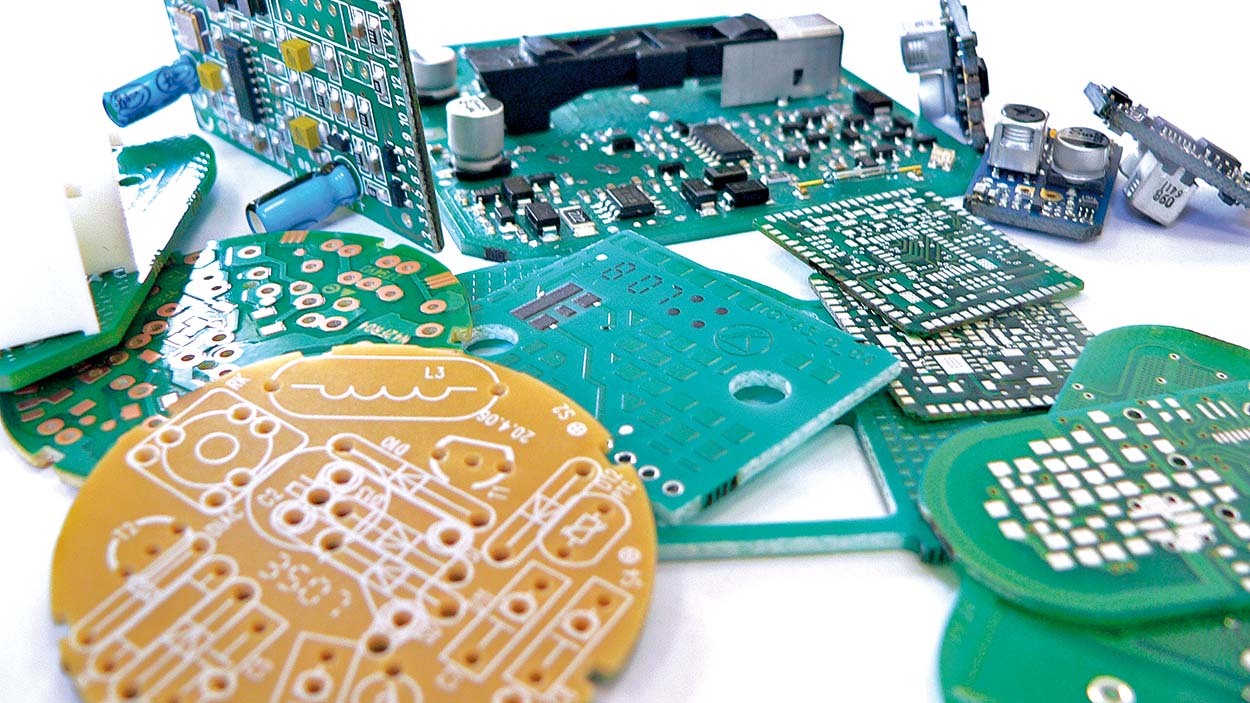

The wide range of available Laser sources (CO2, UV and green) allows the cutting of both rigid boards (FR4) and flexible boards (kapton).

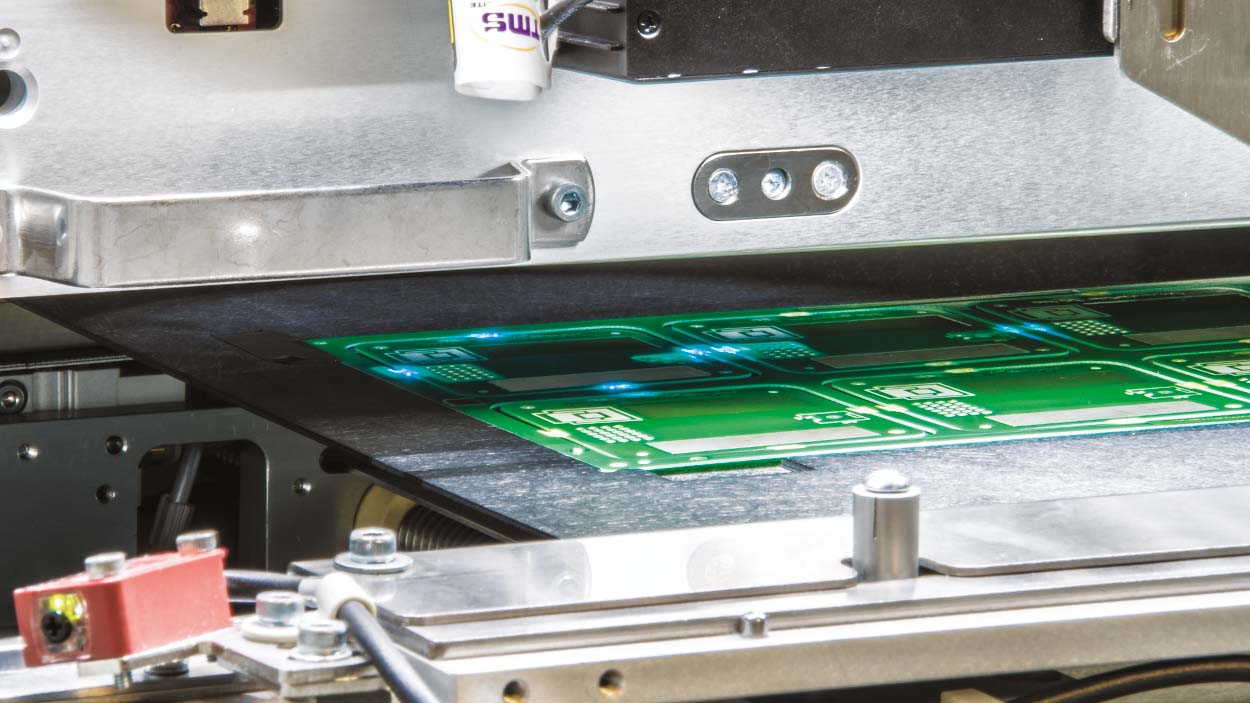

The creation of recipes (cutting programmes) can be done manually: the machine screen displays the image of the board, on which the cutting lines can be ‘drawn’. Alternatively, for greater positioning accuracy, the DXF file of the board can be imported to define the cutting points.

Laser Depaneling for FR4 and flexible PCBs

NeoCut Easy is the solution for Laser cutting of electronic boards. Unlike mechanical depaneling processes (conventional router and blade), Laser cutting is the only process that produces no mechanical stress on the board or its components, thus eliminating the risk of cracks on them. Moreover, it is a process that generates no residue.

The wide range of available Laser sources (CO2, UV and green) allows the cutting of both rigid boards (FR4) and flexible boards (kapton).

The creation of recipes (cutting programmes) can be done manually: the machine screen displays the image of the board, on which the cutting lines can be ‘drawn’. Alternatively, for greater positioning accuracy, the DXF file of the board can be imported to define the cutting points.