Laser welding of polymers for mass production

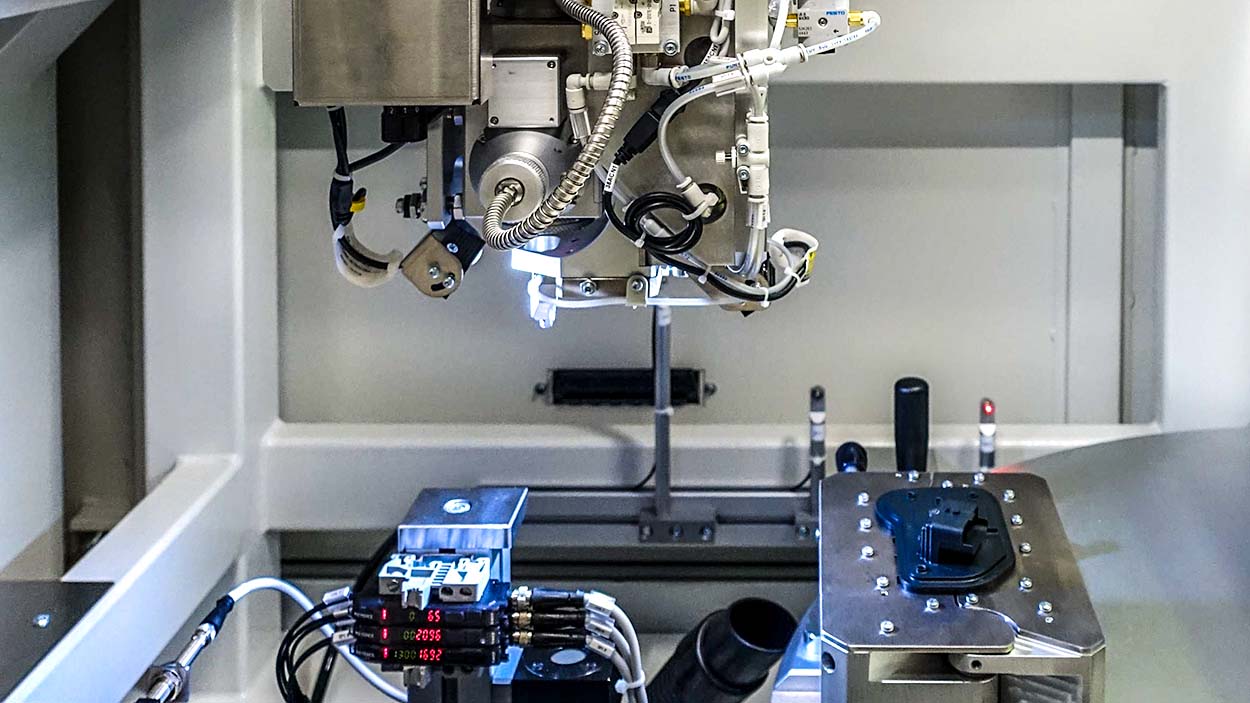

FinePlast 140R is a Class 1 Laser processing system with 700mm diameter rotary table designed for welding plastic components.

The Laser welding of polymers is carried out by putting a transparent material into contact with an absorbent material; the Laser beam crossing the former and heating the latter to fusion point.

The system can be customized to match the geometry of the parts to be weld with CNC-controlled axes and specific tooling to hold the parts in place by applying the right pressure.

Both contour welding and quasi-simultaneous welding using a galvanometric scanner are possible. A pyrometer system can be integrated to monitor the temperature during welding, regulating the laser power in closed loop. A vision system can also be integrated to verify the welding result.

Laser welding of polymers for mass production

FinePlast 140R is a Class 1 Laser processing system with 700mm diameter rotary table designed for welding plastic components.

The Laser welding of polymers is carried out by putting a transparent material into contact with an absorbent material; the Laser beam crossing the former and heating the latter to fusion point.

The system can be customized to match the geometry of the parts to be weld with CNC-controlled axes and specific tooling to hold the parts in place by applying the right pressure.

Both contour welding and quasi-simultaneous welding using a galvanometric scanner are possible. A pyrometer system can be integrated to monitor the temperature during welding, regulating the laser power in closed loop. A vision system can also be integrated to verify the welding result.