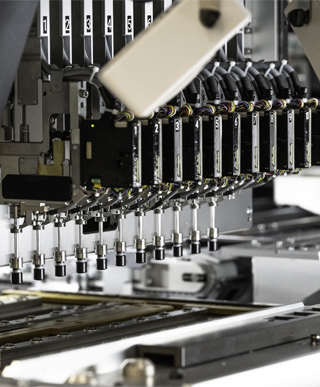

Burn-in Automation.

Burn-in Automation.

Burn-In Testing in Semiconductor Devices.

Burn-In testing, also known as reliability or stress testing, involves subjecting semiconductor devices to prolonged periods of operation and elevated temperatures and voltages. Burn-in testing is a process conducted to identify potential defects or failures. The purpose is to accelerate degradation and identify potential defects or weaknesses in the devices that may lead to failures during their expected lifespan.

Osai Burn-In solutions are tailored to improve the overall reliability of semiconductor components, the brains behind modern electronics; to helps reduce the likelihood of field failures, enhancing customer satisfaction and trust in the brand. While Burn-In testing adds upfront costs to the manufacturing process, it can lead to significant cost savings by reducing warranty claims, returns, and repairs associated with faulty devices, by minimize the number of defective semiconductors shipped to the customers.

Pre-testing, to optimize Burn-In yield and keep

the Burn-In Boards in perfect maintenance