RE4M.

RE4M – Recycling for Manufacturing

Urban mining according to Osai Green Tech SB S.r.L.

Efficient recycling of e-waste is a priority global goal. In addition to the environmental impact generated by e-waste, estimated at more than 57 million tons in 2021 (source RSC Royal Society of Chemistry), its treatment is becoming more essential than ever as a sustainable alternative to mining critical and precious metals from underground.

A study conducted by The European Ambrosetti House for Erion, also highlights that Italy is at risk of supplying critical raw materials (CRMs) essential for the development of strategic sectors for the country’s economy such as the aerospace, electronics, automotive and renewable energy industries.

In fact, Italy’s industrial production depends for 564 billion euros (one third of GDP as of 2021) on the import of non-EU critical raw materials. A scenario aggravated by the current Russian-Ukrainian conflict as Italy depends on Russia for Palladium, Rhodium, Platinum and Primary Aluminum.

Urban mining, or the enhancement of urban mining through the extraction of critical and precious metals contained in disused electronic devices represents a necessary and inevitable revolution to ensure continued technological and sustainable evolution.

Increasing the recycling rate of WEEE through efficient and sustainable processes would generate significant environmental benefits such as a reduction of nearly 1 million tons of CO2, which would translate into social benefits for the community quantifiable at about 208 million euros. Finally, the increased availability of critical raw materials to support the country’s entire economy would reduce the cost of imports, generating an economic benefit estimated at nearly 14 million euros.

OSAI’s experience within the European ADIR project, allows us to say with certainty that applying automation to the recycling world where everything or almost everything is done by hand, generates great value and new opportunities including employment.

Automation brings efficiency, application of new technologies, speed, quality and guarantees value in raw material recovery.

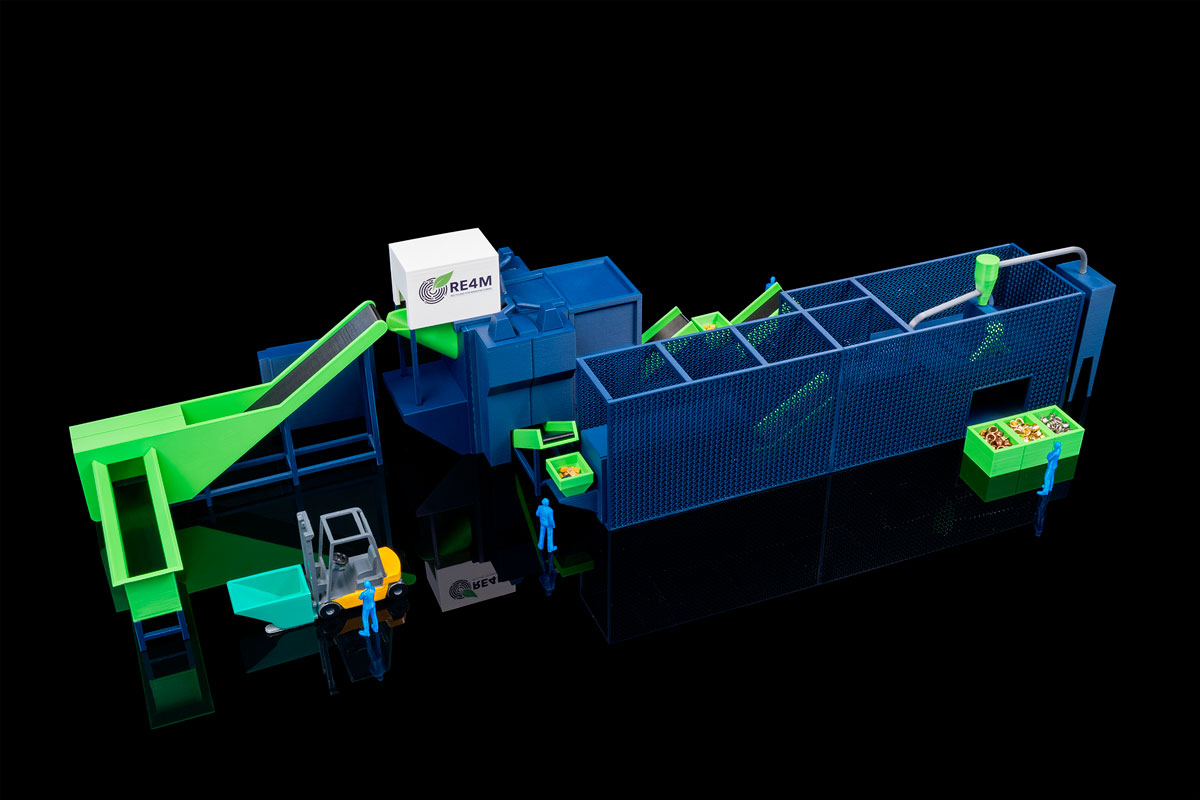

From this insight, combined with more than 30 years of experience in the automation world, comes the RE4M project, an innovative system for the automated extraction and selection of electronic components for the recovery of critical and precious metals. The project, launched in 2020 and which will see the first plant in 2023, on which the Company aims to invest 5 million euros, will allow the best existing technologies and experiences to be applied to the world of electronic waste recycling (WEEE), transforming the waste into new raw material to be included within new production processes with a view to the circular economy.

The plant thus conceived will later enable the efficient refining of metals such as gold, silver, palladium and copper. The technology developed by Osai will allow, in combination with the technologies of its partner BTT Italia S.r.l., high levels of efficiency with low environmental impacts.

The RE4M project was presented during 2021 at the Ecomondo trade fair in Rimini, a reference event in Europe for the ecological transition and the circular and regenerative economy, arousing the interest of the main market players, reinforcing the conviction that automation in recycling will be the “key factor” in the coming years, the indispensable technological element to make efficient material recycling processes and thus the creation and regeneration of value from waste.

In 2022, the Osai Group presented during the XXVI edition of Ecomondo the newly-established Osai Green Tech SB S.r.l. founded with the aim of actively contributing to the diffusion of automation in the recycling world, bringing efficiency, speed and sustainability, thanks to the parent company’s thirty years’ experience in industrial automation, with the ambition of becoming a primary technological partner alongside the main national and international players committed to the ecological transition and circular economy, offering innovative products characterised by the latest technologies in the field of automation and Industry 4.0.

The company pursues its corporate purpose in a transparent and responsible manner, balancing the interests of its shareholders and the aims of common benefit derived from the development and commercialisation of the RE4M project, while also promoting innovative applications for recycling and the circular economy.

The plant, and its innovative technology which is covered by a patent, is strategically aligned with European policies and those reported within the PNRR – National Recovery and Resilience Plan and in particular in the action defined as “Circular Economy and valorization of the integrated waste cycle“, which envisages investments of 4.5 billion euros aimed at the increase and recovery of waste from electrical and electronic equipment (WEEE) and the construction and modernization of recycling plants.

RE4M – Recycling for Manufacturing

Urban mining according to Osai Green Tech SB S.r.L.

Efficient recycling of e-waste is a priority global goal. In addition to the environmental impact generated by e-waste, estimated at more than 57 million tons in 2021 (source RSC Royal Society of Chemistry), its treatment is becoming more essential than ever as a sustainable alternative to mining critical and precious metals from underground.

A study conducted by The European Ambrosetti House for Erion, also highlights that Italy is at risk of supplying critical raw materials (CRMs) essential for the development of strategic sectors for the country’s economy such as the aerospace, electronics, automotive and renewable energy industries.

In fact, Italy’s industrial production depends for 564 billion euros (one third of GDP as of 2021) on the import of non-EU critical raw materials. A scenario aggravated by the current Russian-Ukrainian conflict as Italy depends on Russia for Palladium, Rhodium, Platinum and Primary Aluminum.

Urban mining, or the enhancement of urban mining through the extraction of critical and precious metals contained in disused electronic devices represents a necessary and inevitable revolution to ensure continued technological and sustainable evolution.

Increasing the recycling rate of WEEE through efficient and sustainable processes would generate significant environmental benefits such as a reduction of nearly 1 million tons of CO2, which would translate into social benefits for the community quantifiable at about 208 million euros. Finally, the increased availability of critical raw materials to support the country’s entire economy would reduce the cost of imports, generating an economic benefit estimated at nearly 14 million euros.

OSAI’s experience within the European ADIR project, allows us to say with certainty that applying automation to the recycling world where everything or almost everything is done by hand, generates great value and new opportunities including employment.

Automation brings efficiency, application of new technologies, speed, quality and guarantees value in raw material recovery.

From this insight, combined with more than 30 years of experience in the automation world, comes the RE4M project, an innovative system for the automated extraction and selection of electronic components for the recovery of critical and precious metals. The project, launched in 2020 and which will see the first plant in 2023, on which the Company aims to invest 5 million euros, will allow the best existing technologies and experiences to be applied to the world of electronic waste recycling (WEEE), transforming the waste into new raw material to be included within new production processes with a view to the circular economy.

The plant thus conceived will later enable the efficient refining of metals such as gold, silver, palladium and copper. The technology developed by Osai will allow, in combination with the technologies of its partner BTT Italia S.r.l., high levels of efficiency with low environmental impacts.

The RE4M project was presented during 2021 at the Ecomondo trade fair in Rimini, a reference event in Europe for the ecological transition and the circular and regenerative economy, arousing the interest of the main market players, reinforcing the conviction that automation in recycling will be the “key factor” in the coming years, the indispensable technological element to make efficient material recycling processes and thus the creation and regeneration of value from waste.

In 2022, the Osai Group presented during the XXVI edition of Ecomondo the newly-established Osai Green Tech SB S.r.l. founded with the aim of actively contributing to the diffusion of automation in the recycling world, bringing efficiency, speed and sustainability, thanks to the parent company’s thirty years’ experience in industrial automation, with the ambition of becoming a primary technological partner alongside the main national and international players committed to the ecological transition and circular economy, offering innovative products characterised by the latest technologies in the field of automation and Industry 4.0.

The company pursues its corporate purpose in a transparent and responsible manner, balancing the interests of its shareholders and the aims of common benefit derived from the development and commercialisation of the RE4M project, while also promoting innovative applications for recycling and the circular economy.

The plant, and its innovative technology which is covered by a patent, is strategically aligned with European policies and those reported within the PNRR – National Recovery and Resilience Plan and in particular in the action defined as “Circular Economy and valorization of the integrated waste cycle“, which envisages investments of 4.5 billion euros aimed at the increase and recovery of waste from electrical and electronic equipment (WEEE) and the construction and modernization of recycling plants.